How to Make Stickers : DIY Methods and Ordering Guide

Labels and stickers significantly impact the image of the items they are attached to or the products themselves. Attaching original stickers to products can enhance visibility, promote sales, and aid in branding.

Some people may consider making their own stickers without relying on a professional printing company. This article explains how to make stickers yourself and the process of ordering from a printing company.

Please feel free to contact us.

There Are Two Options for Making Labels and Stickers

When creating labels, stickers, or seals, there are two main options:

- Make them yourself

- Order from a professional printing company

Option 1: Make Them Yourself

If the design is simple, you can make stickers yourself. By purchasing special paper online and printing with a standard printer, you can create your favorite stickers in small quantities.

However, the functionality, texture, and feel of the stickers will be significantly different from those ordered from a printing company. Additionally, household printers may not use waterproof ink, so you need to be cautious about smudging.

If you make them yourself, it is recommended to limit their use to personal items like sorting labels for tasks.

Option 2: Order from a Professional Printing Company

If you care about quality, it's best to order from a company that specializes in sticker printing. They will listen to your requirements regarding material, design, and purpose to create stickers that meet your needs.

Moreover, stickers made by printing companies are cured with UV light, making them resistant to smudging. By incorporating special processing or unique materials, you can also differentiate from competitors.

However, the cost tends to be higher due to the detailed interactions required. When making stickers, it's essential to choose the best method based on your budget and purpose.

Steps to Make Labels and Stickers Yourself

The main methods and steps for making labels and stickers yourself are as follows:

- Purchase commercially available sticker paper (tack paper)

- Create the design using a computer or smartphone

- Print with a printer

- Cut to the desired size

With the above steps, anyone can easily make labels and stickers themselves.

However, it is not suitable for mass production, and there are limitations in design and quality. You will also need to cut the stickers with a cutter or scissors after printing, which takes time and effort.

While DIY stickers and labels are fine for personal use, it is recommended to order from a printing company for product labels and stickers. The specific process is explained in the next section.

Steps to Order Labels and Stickers from a Printing Company

When ordering from a sticker printing company, the general process is as follows:

- Quotation

- Design creation

- Order and submission

- Sample check

- Product delivery

Step 1: Quotation

Before requesting a quotation, it is best to decide on the following three points:

- Dimensions

- Number of colors

- Quantity

Having a clear image of the sticker you want to make allows for an accurate quotation, making it easier to budget.

The optimal materials and methods vary even for commonly seen items like food labels and bottle labels. If you are unsure, use the inquiry form or consult during the quotation request.

Step 2: Design Creation

Generally, you provide your own design, but some printing companies offer comprehensive services. When deciding on a design, it is important to specifically imagine not only the finished product but also how it will be used.

If you want to incorporate special processing techniques such as foil stamping or embossing, be sure to communicate these details.

Step 3: Order and Submission

Once the specific design and cost are finalized, place your order and submit the design data.

Delivery dates are generally decided at this stage, so it is important to request them with a sufficient schedule. After confirming the order, the sticker printing company will start production based on the data.

Step 4: Check the Sample

If you are worried about your first order or want to check the details before mass production, request a paid sample (proof).

You can check if the sample matches your expected finish before full production begins. If the sample does not meet your expectations, you can discuss adjustments at this stage.

Once the official production starts, changes are generally not possible at any printing company. If possible, it is recommended to create a sample and carefully check the color, texture, and details of the design.

Step 5: Product Arrival

If you are satisfied with the sample, just wait for the actual product to arrive. The time it takes to complete depends on the order quantity, design, and timing.

Be aware that rush orders may incur additional costs, or it may not be possible to place an order at all. Plan carefully, considering the time you need the stickers. You can consult with an experienced representative at our company for product label creation. Please feel free to contact us through the inquiry form.

5 Types of Stickers to Enhance Product Appeal and How to Make Them

There are many styles of labels and stickers. Here are five representative processing techniques.

- Foil Stamping Stickers

- Embossed Stickers

- Domed Stickers

- Ribbon Stickers

- Multilayer Labels

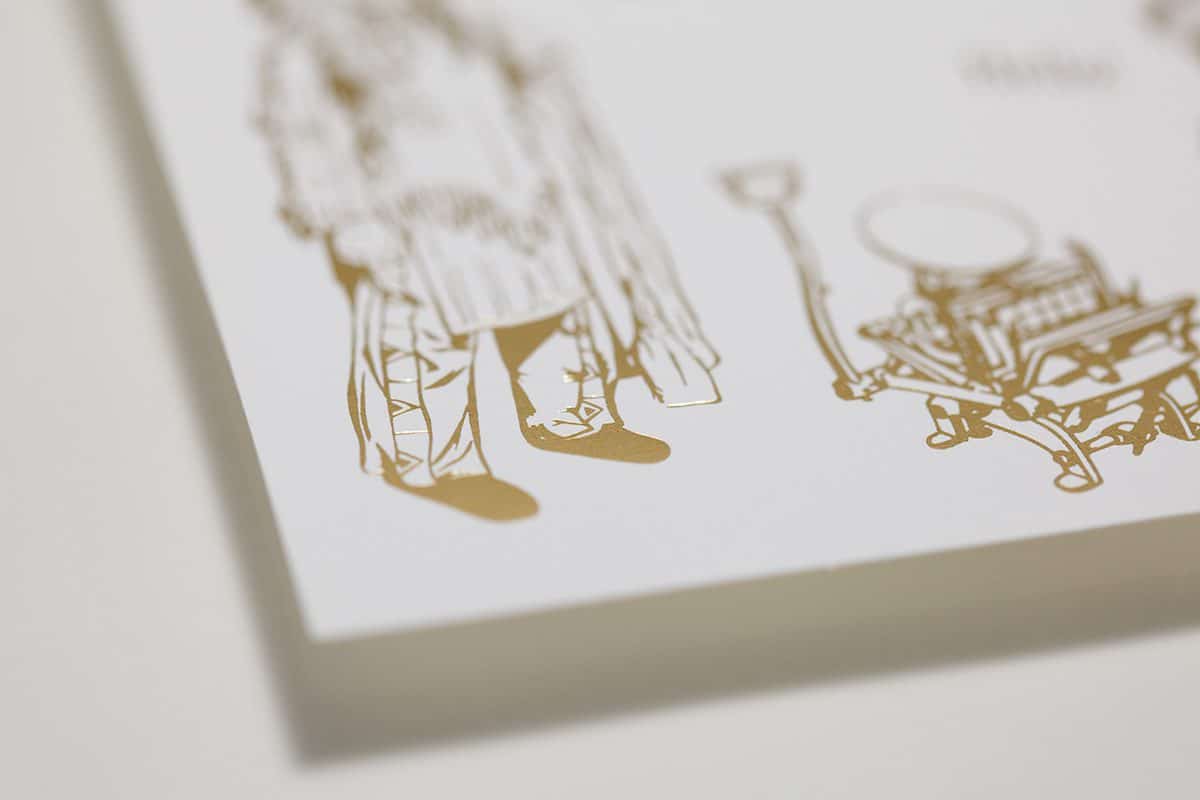

Type 1: Foil Stamping Stickers

"Foil stamping" is a technique that applies gold or silver foil to logos or highlighted parts. There are two methods: hot stamping and cold foil.

Hot stamping involves placing foil between a copper plate (the die) and the printed material, and applying high heat and pressure to adhere the foil. Cold foil involves printing a special adhesive on the areas where the foil will be applied and then transferring the foil onto those areas.

The mainstream method is hot stamping, which offers excellent cost performance. It is used in various materials, such as common stickers and labels. The appeal of this processing method is that it can be introduced at a reasonable price while providing a luxurious feel.

Production Example: Heso Inc. Embossed Foil Stamping Stickers

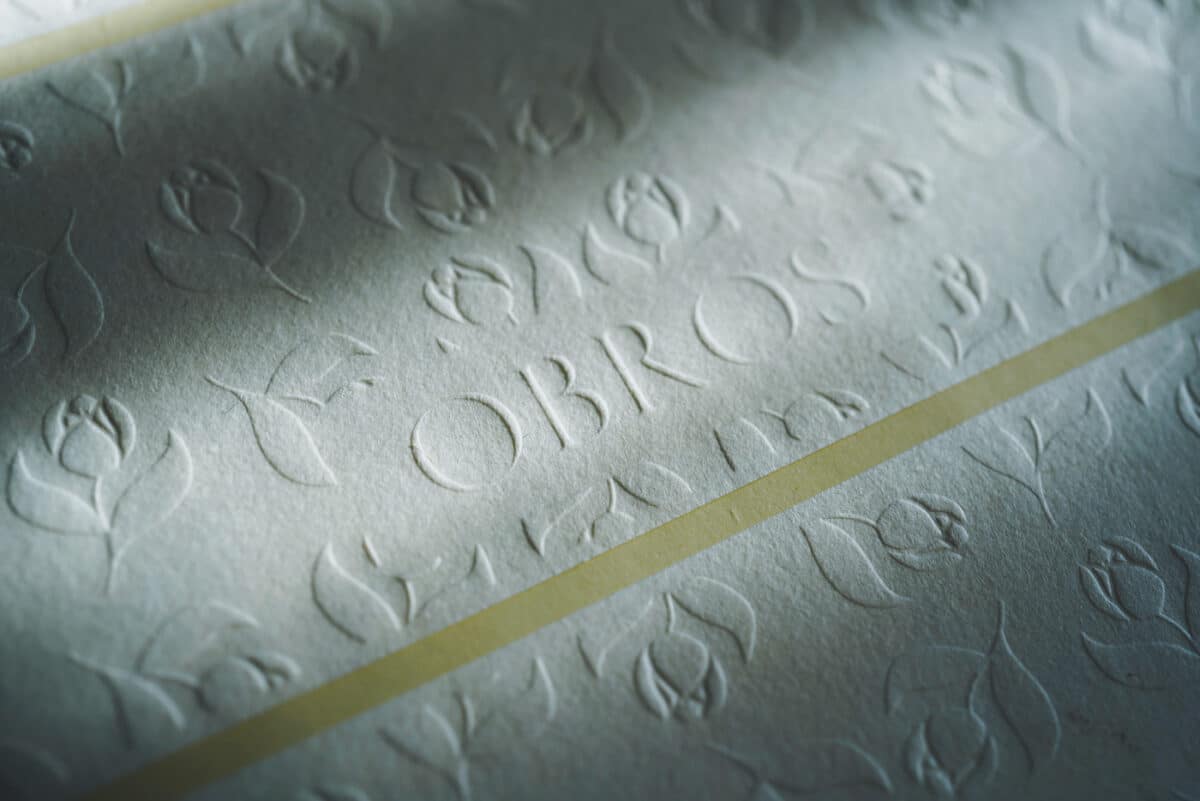

Type 2: Embossed Stickers

Embossing is a technique that creates a three-dimensional pattern or design by applying pressure to paper materials. It is often used for emphasizing brand logos, product names, etc. It is a versatile processing method that is modest yet luxurious. However, embossing is generally limited to paper materials. It is not recommended for film materials as embossing is extremely difficult.

Each printing company has its own technology, so even the same design may vary in the degree of embossing. It is recommended to get samples in advance to check if the printing company's style matches your preferences.

Production Example: KOU Inc. Embossed Foil Stamping Stickers

Type 3: Domed Stickers

Domed stickers are stickers with a domed coating of urethane resin on the printed surface. The resin is applied in a calculated amount to the sticker, and after being left to dry for a long time, a sticker with a thickness of about 2mm is created.

Since resin is applied using surface tension, it cannot be domed on complex or angular shapes. It is highly resistant to water and durability, making it suitable for outdoor use. Domed stickers add impact to stickers, and they are used for logos and emblems in various industries. While being the most expensive type of sticker, its elegant appearance and durability give it a strong appeal. However, it cannot be applied to curved surfaces due to its strong repellent force. It is only suitable for flat surfaces.

Production Example: Hitsuji Sunrise Domed Stickers

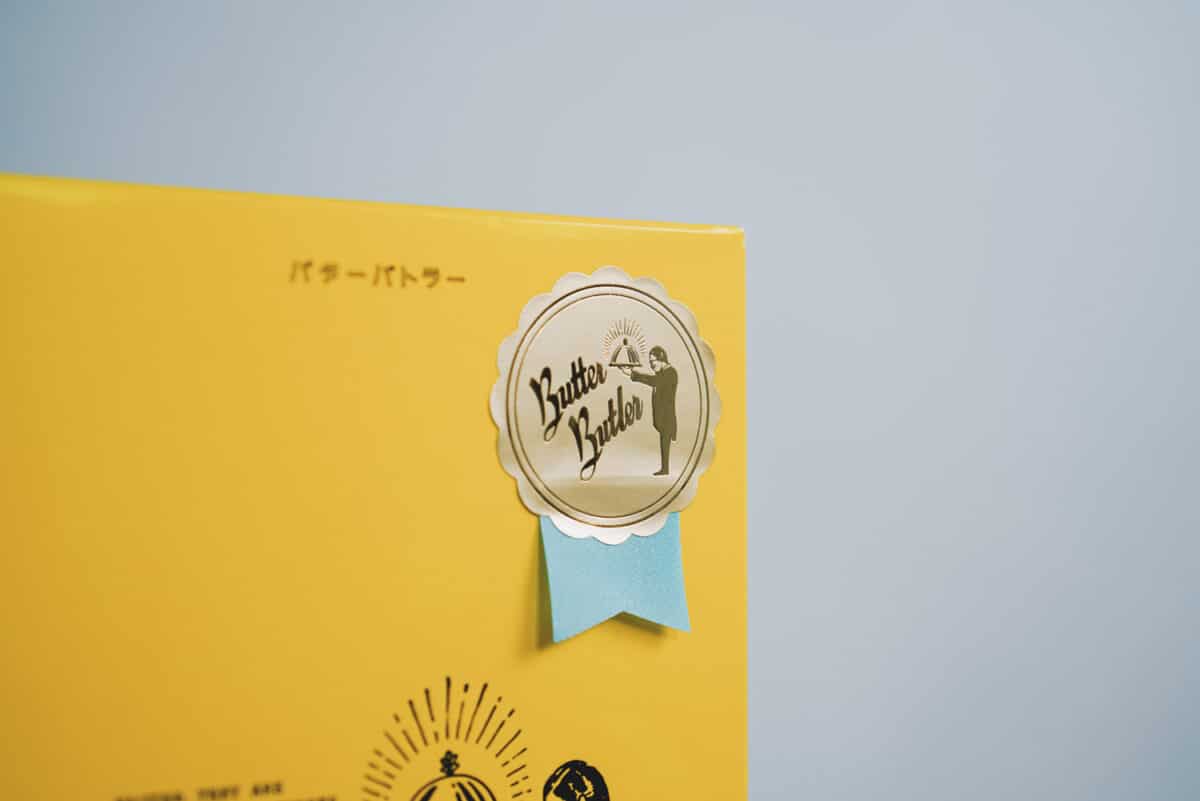

Type 4: Ribbon Stickers

Ribbon stickers, as the name suggests, are decorative stickers with attached ribbons. They add a touch of thoughtfulness and elegance to gifts and products. You can easily create them at home by attaching a ribbon to the back of a sticker.

If you custom-order from a printing company, incorporating foil stamping or embossing can create a luxurious ribbon sticker. The versatility of combining elements allows for both casual and formal designs.

Production Example: Sucrey Ribbon Stickers

Type 5: Hologram Stickers

Hologram stickers are special stickers that shine in seven colors depending on the angle of the light.

Since special processing technology is required for the multi-colored shimmering film, they are generally manufactured and sold only by specialized manufacturers.

Most printing companies purchase holographic film from manufacturers and perform secondary processing to create stickers. They are highly noticeable and are often used for special products or novelty stickers.

Production Example: Illuminate Corp. Holographic Film

All the types of stickers introduced here are available from our company. If you are interested in any type, please feel free to contact us through the inquiry form.

5 Points to Keep in Mind When Ordering Custom Stickers

When creating original stickers for your company, it is important to keep the following five points in mind.

- Material

- Proofing (Sample)

- Adhesive Type

- Printing Method

- Delivery Format

Point 1: Material

Traditionally, paper or film materials were commonly used for stickers, but in recent years, environmentally friendly materials have been increasing.

The main materials currently used for stickers are as follows:

- Paper

- Film

- Environmentally Friendly Materials

Among these, environmentally friendly sticker materials include LIMEX made from limestone and Eco Marine Tack, which is biodegradable. LIMEX is said to reduce the risk of water resource waste and water pollution as it can be produced with much less water compared to traditional paper-making processes.

For more details about LIMEX, please refer to the following article:

Learn More About LIMEX

Point 2: Proofing (Sample)

Proofing (sample) is the process of creating a paid print sample to check the colors before commercialization.

The cases where proofing is necessary and where it is not necessary are as follows:

| Proofing Required | Proofing Not Required |

| When there is a corporate color For four-color printing When printing a large quantity | When there is a color sample When instructions can be given using PANTONE or DIC |

If there are clear standards, such as color samples, there will be no color discrepancies even without proofing.

On the other hand, in four-color printing, it is easier to achieve color differences depending on the printing method and ink, so it is better to do proofing. Proofing is also necessary when there are corporate colors or large print runs where color deviations are unacceptable.

For more detailed procedures on proofing, please refer to the following article:

Sticker Printing Color Proofing | An Important Process to Avoid Color Recognition Issues

Point 3: Adhesive Type

There are various types of adhesives for stickers. The main types and their characteristics are as follows:

| Adhesive Type | Characteristics |

| General Adhesive | Can be used in a wide range of situations |

| Strong Adhesive | Harder to peel off than general adhesive |

| Weak Adhesive | Designed to be eventually removed Weak adhesive strength |

| Cold-Resistant Adhesive | Maintains adhesive strength even when cooled Available for refrigeration and freezing |

| Oil-Resistant Adhesive | Sticks well even to oily surfaces |

In addition to these, there are many other adhesive types.

The optimal choice varies depending on the application. For more details, please see the following article:

A Comprehensive Guide to Sticker Adhesive Types

Point 4: Printing Method

The main printing methods commonly used for stickers and labels are as follows:

| Printing Method | Features |

| Relief Printing | Recommended for those prioritizing cost Transfers ink to the material using a raised plate Low-cost mass production possible Most commonly used for label printing |

| Offset Printing | Recommended for those prioritizing quality Uses the principle of oil and water repelling each other to distribute ink on the print surface High reproducibility for detailed, high-quality results |

| Silk Printing | Suitable for parts requiring durability Uses the action of ink passing through the mesh of a screen Can apply thick ink layers, making it resistant to wear and fading Suitable for outdoor use |

| Inkjet Printing | Suitable for small-lot, durability-focused prints Also known as on-demand printing Directly sprays ink onto the print surface, no need for plates Low cost for small quantities, but high cost for mass production |

When deciding on a printing method, it is important to choose one that matches your budget and the desired image of the finished product.

For more detailed information, please refer to the following article:

Supported Printing Methods

Point 5: Delivery Format

There are generally five patterns for the final delivery format of stickers. The main features are as follows:

| Finish Type | Features | Suitable Products |

| Sheet Cut | Multiple stickers on a sheet Convenient for manual application | Product Labels |

| Single Cut | One sticker per sheet Often used for distribution purposes | Stickers |

| Roll | Stickers rolled onto a core Suitable for automatic labeling machines | Product Labels |

| Trimmed | Sticker and backing are the same size (rectangular) Trimmed on all sides | Stickers |

| Die Cut | Sticker and backing are the same size (shaped) Punched out with a die | Stickers |

When producing stickers or labels, it is important to choose the optimal delivery format according to the intended use.

While considering the convenience of the application process, if the purpose is distribution, it may be better to prioritize appearance.

For more details on sticker delivery formats, please refer to the following article. The article also features images of the different styles, so it can be a helpful reference.

Five Types of Sticker Finishes Based on Use

Learn the Process to Create Stickers as You Imagine

As introduced, there are two main methods to create stickers: self-production and outsourcing to a printing company.

While self-production is possible, general printers may result in lower print quality and increased smudging. Additionally, the process requires cutting with scissors or other tools, which can be time-consuming.

On the other hand, stickers produced by printing companies use water-resistant and durable inks, making them less prone to smudging and suitable for use around water and outdoors. If quality and convenience are priorities, especially for product labels, consulting with a printing company is advisable.

Our company supports a wide range of sticker production types as introduced in the article. If you are considering creating stickers, please feel free to contact us from the link below. Quotes are available 24 hours a day.

Start Your Project Now!

Contact Us or Get a Quote!