How to Create Label Stickers: DIY and Using a Print Company

Label stickers play a crucial role in conveying the information and appeal of products whose contents are not visible. They are also commonly used for addressing envelopes and packages.

There are various methods of creating label stickers, including DIY and outsourcing to printing companies, each with different costs. To differentiate your product and showcase originality, it's important not to compromise on the creation process. This article explains how to create label stickers yourself and highlights key points for differentiation.

As a specialist in label and sticker printing, our company has extensive experience in creating a wide variety of label stickers. If you want to attach attractive label stickers to your products, please contact us below. We will respond promptly.

Please feel free to contact us.

Two Ways to Create Label Stickers

There are mainly two methods for creating label stickers to attach to products or packages:

- Create them yourself using Excel and Word

- Outsource to a sticker printing company

Method 1: Create Them Yourself

When creating label stickers yourself, the common method is to create the data on a computer and print it using a printer. You can easily create just one sheet and print whenever you like. If you don't have a printer, you can use the print services at convenience stores.

Method 2: Outsource to a Sticker Printing Company

If you are particular about the quality, it is recommended to leave it to a specialized label and sticker printing company. Although it takes time for estimates and design consultations until completion, you can create detailed labels that meet your specifications.

Compared to online printing services where you handle the process yourself, it may be slightly more expensive, but the high-quality finish helps differentiate your products. If you are looking for value-added labels such as product labels, consider outsourcing to a printing company.

For more details on the specific process of outsourcing to a printing company, please refer to the later section of the article, "The Process of Creating Label Stickers by Outsourcing to a Printing Company".

Four Steps to Create Address Label Stickers Using Word and Excel

The general process of creating address label stickers using Word and Excel is as follows:

- Prepare label paper for addresses

- Enter addresses in Excel

- Use the mail merge feature in Word

- Import Excel data and print with a printer

Step 1: Prepare Label Paper for Addresses

First, prepare specialized label paper. Often referred to as "tack seals", A4 size is common for address labels.

There are various types of label shapes, so be careful not to make a mistake when purchasing.

Step 2: Enter Addresses in Excel

Open Excel and enter the items you want to include in the address in the top row. Including fields such as postal code, address, and name, as well as a management number for the recipient, can make it easier to manage.

Enter the data such as names and addresses. Since the entered content will be reflected directly on the label, be careful to avoid mistakes in characters and titles.

Step 3: Use the Mail Merge Feature in Word

Launch Word and click "Start Mail Merge" followed by "Mail Merge Wizard".

Set the document type to "Labels" on the mail merge screen.

Open the "Label Options" settings and select the product number of the address label paper.

Step 4: Import Excel Data and Print

Select "Use an existing list" from "Select Recipients".

Select the Excel address list you created earlier.

Reflect the contents of the address list onto the labels and finalize the design. Use the Enter key (line breaks) and the Space key (spaces) to balance the placement of text.

Once completed, check the design in the preview. The design displayed on the screen will be printed as it is, so make a final check to ensure there are no issues.

Print the address labels to complete the label stickers. When setting the paper in the printer, be careful not to print on the wrong side.

Five Steps to Create Label Stickers by Outsourcing to a Printing Company

The general process for ordering label stickers from a printing company is as follows:

- Request a Quote

- Create the Design

- Order and Submit Data

- Check the Prototype

- Receive the Final Product

Step 1: Request a Quote

First, enter the necessary information in the quote form on the website to get a free quote. The more concrete your image of the label's size, shape, quantity, etc., the more accurate the quote will be.

If you are unsure about the appropriate material or adhesive type, you can consult before placing your order. One advantage of outsourcing to a printing company is that they can propose the best options when you're unsure.

Step 2: Create the Design

Once you have an idea of your budget, finalize the label design. While it's common to create the design in-house, if you want to streamline the process, choose a printing company that can also handle the design.

The design is a crucial point that affects the product's appeal, so it's important not to compromise. Imagine the label on the actual package or bottle and create something you are satisfied with.

Step 3: Order and Submit Data

Once the design is completed, submit the design data to the printing company when placing your order. The process usually includes adjustments such as color proofing and prototype creation.

Some printing companies offer paid pre-production prototypes. While it may take some time and effort, it is recommended to proceed carefully to ensure the product is finished as desired. Since you are outsourcing to a printing company with high standards, take each step without compromise.

Step 4: Check the Prototype

Once the prototype is completed, make sure to check it against the actual product to ensure it meets your expectations. If there are any changes needed, such as adjustments to the design, address them at this stage.

If major production begins and changes are needed, additional costs and time may be required. To avoid trouble, perform the confirmation process carefully.

Step 5: Receive the Final Product

The process is officially complete when the finished labels are delivered. Although it varies by printing company, it is common for the printing plates to be stored for a certain period. If you reorder during the storage period, the plate creation cost will not be incurred, making it cheaper than the initial order.

If there is a possibility of creating the same design again, be sure to confirm the storage period. At our company, plates and die-cuts are stored for three years from the last order. If you are considering creating label stickers for products, please feel free to contact us through the "Contact Us" form.

Three Key Points for Differentiating Label Stickers

To highlight the appeal of your product with label stickers, here are three key points to consider:

- Special Processing

- Material

- Shape

Point 1: Special Processing

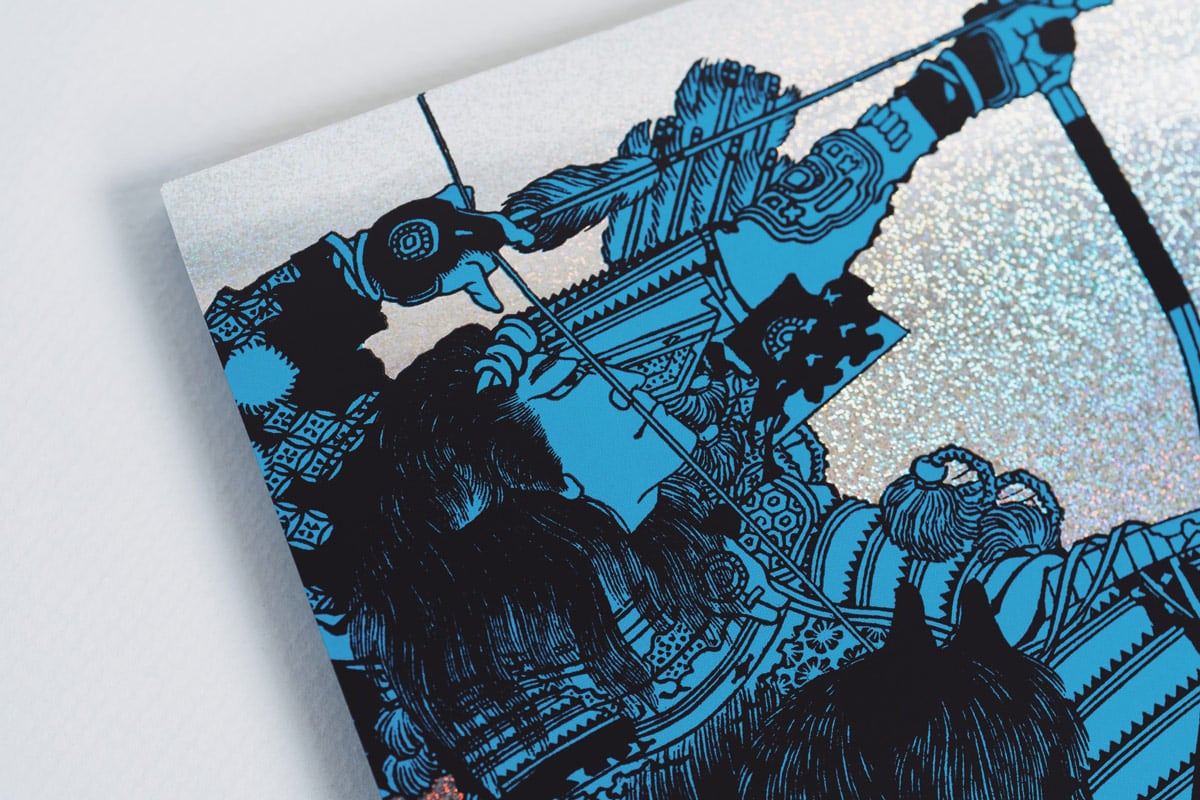

In addition to general printing of designs, there are many special processing techniques for label stickers. The main ones are as follows:

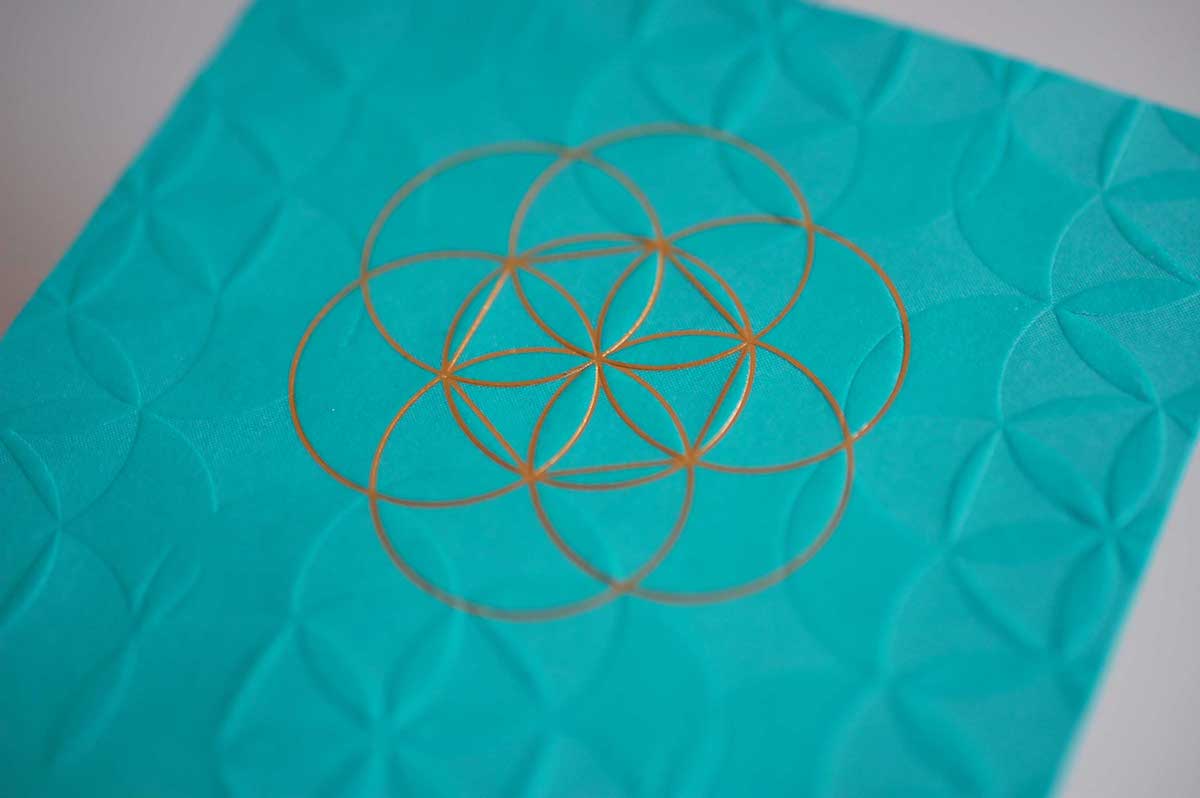

- Foil Stamping

- Embossing

- Double-sided Printing

Foil stamping is a processing technique where "foil" is hot-pressed onto logos or parts you want to emphasize. It is suitable for creating a luxurious feel.

Embossing uses raised and lowered surfaces to express designs, offering a refined impression while being subtle.

Double-sided printing allows the print to be seen from the adhesive side as well. Using this on labels for clear bottles can attract consumer interest, adding flair from any angle.

Even if you are not familiar with these processing techniques, consulting with a specialist can help you get optimal suggestions based on your image and design. Using these techniques strategically, either as a focal point or balanced throughout, can make your product more effective.

Point 2: Material

Label sticker materials are generally divided into the following two categories:

- Paper Material

- Film Material

The characteristic of paper material is the wide variety of textures, ranging from natural to smooth surfaces. It is also compatible with foil stamping and embossing, making it suitable for creating a luxurious feel. The unique texture of the material can be incorporated as part of the design.

Film material is highly durable and waterproof, making it suitable for outdoor or water-related use. It is often used in situations where strength is required, as it can withstand repeated attaching and peeling.

Both paper and film materials have a wide range of options, from widely used to highly unique types. Choose the best material based on the final image and intended use.

Point 3: Shape

Deciding on a custom-made label shape is a strength unique to specialized companies that can thoroughly discuss the design stage. In addition to common shapes like rectangles and ovals, labels can be tailored to the unique shape of each product. The high degree of freedom allows for the creation of original and sophisticated atmospheres.

However, special shapes such as jagged edges or custom silhouettes tend to be more expensive than simple rectangles or circles. It is important to check the costs in advance.

Our company can create stickers with a wide range of materials and processing methods. If you have a specific material, shape, or design concept in mind, please feel free to contact us for a quote.

Three Reasons to Pay Attention to How You Make Label Stickers

Here are three reasons why you should be particular about where you order your label stickers:

- High Visual Quality

- Excellent Functionality

- Enhanced Product Value

Reason 1: High Visual Quality

Labels completed through repeated trials with specialized companies are of high quality. You can create labels that pay close attention to details such as texture, color, and reproducibility.

If you want to highlight the uniqueness of your product and create a sense of luxury or specialness, custom-made label creation is recommended. A specialized company can create labels that meet your goals with their technical skills and thorough listening.

Reason 2: Excellent Functionality

Labels created by specialized companies are also excellent in terms of functionality. The usability of a label is greatly influenced by the material and type of adhesive used.

Adhesive strength, ease of removal, and adaptability to temperature differences are all factors that need to be considered to create highly convenient labels. The ability to propose the best options based on not only design but also the product's purpose is another advantage of using a specialized company.

Reason 3: Enhanced Product Value

Labels created by a specialized company effectively enhance the added value of the product. Since they are custom-made, they have a high degree of uniqueness and can express the charm of the brand or product.

Incorporating processing techniques such as foil stamping or using high-quality materials can make the product itself one-of-a-kind. Most products cannot be tested before purchase. Therefore, focusing on enhancing the perceived value through the label plays an important role in conveying the product's appeal.

For Commercial Label Stickers, Use a Specialized Printing Company

Labels are the "face" of a product, influencing brand image and sales. They are an important tool for creating a sense of luxury and atmosphere, so it is necessary to use them effectively.

While inexpensive and simple labels are not bad, the difference in cost and effort can lead to differences in the final product. If you want to differentiate yourself from competitors, consider using a specialized printing company.

Our company can create custom-made label stickers that enhance the appeal of your products and brand. Inquiries and quotes are available 24 hours a day, so please feel free to contact us.

Start Your Project Now!

Contact Us or Get a Quote!