Product Label Design Tips: A Guide to Creation and Materials

Product labels play a crucial role in conveying product information and image to consumers. The design of product labels is important as it greatly affects sales.

In this article, we introduce points to consider when creating product labels, methods to make them yourself, and information about materials. If you are planning to create product labels, please refer to this guide.

As a company specializing in label and seal printing, we also create product labels. If you wish to create attractive labels tailored to your products, feel free to contact us.

Please feel free to contact us.

Can Product Labels Be Made Yourself?

If the quantity is small, you can purchase specialized paper and create simple labels with a home printer. If you are unsure about the design, we recommend using tools with prepared templates.

However, please note that homemade labels may differ in functionality, feel, and durability compared to product labels ordered from a professional printing company.

How to Make Product Labels

The main steps to make product labels yourself are as follows:

- Create the design on a computer or smartphone

- Prepare commercially available label paper

- Print with a printer

- Cut the printed labels to the desired size

Step 1: Create the Design on a Computer or Smartphone

First, create the product label design. We recommend using free tools such as Canva, Adobe Express, or Photoshop for creating the design.

For example, Canva allows you to create labels based on templates, making it easy for those who are not confident in their design skills.

Step 2: Prepare Commercially Available Label Paper

Next, prepare the paper for printing.

We recommend using "tack paper" for product label paper. Tack paper has an adhesive back and is used for printing labels, seals, and stickers.

There are two types of materials: "paper material" and "film material." Choose the material according to your purpose.

Step 3: Print with a Printer

Print with a home printer. However, note that home printers have limitations for large-scale printing and may affect the print quality.

Especially, ink may bleed, so be careful if there are fine designs or small text.

Step 4: Cut the Printed Labels to the Desired Size

After printing, use scissors or a cutter to cut the labels to the required size. Cutting requires carefulness, so it is a time-consuming and labor-intensive task until completion.

While it is possible to make product labels yourself, there are limitations in design, quality, and quantity. When making them yourself, it is important to consider these points.

If You Want to Create High-Quality Product Labels, It Is Recommended to Order from a Label Printing Company

Product labels influence customer purchase decisions and sales. By ordering from a label company, you can discuss materials and design preferences and create product labels according to your requirements.

Using special processing or unique materials for product labels can help differentiate your product from others.

The main steps for creating product labels with a printing company are as follows:

- Requesting a quote

- Design creation

- Order and submission

- Checking the sample

- Receiving the product

When requesting a quote, having decided on the label size, color count, and quantity will allow for a clear estimate.

We are a printing company that produces product labels and seals. If you are considering creating product labels or have a specific image in mind, please feel free to contact us through "Contact Us".

Materials, Adhesives, and Processing Features Required for Creating Product Labels

When ordering product labels, it is helpful to know about the materials, types of adhesives, and processing methods used. Here, we will introduce the types and characteristics of each, which can be useful when ordering product labels.

Materials for Product Labels

First, let's introduce the types and characteristics of the materials (paper).

The main materials for product labels are as follows:

| Material | Characteristics |

| High-Quality Paper | ・Used for a wide range of applications ・Rich color variations ・Used for food labeling and quality control labels ・Has a smooth texture like copy paper |

| Art Paper | ・Paper coated with white pigment on the surface of high-quality paper ・Glossy and has a high-end feel ・Good color rendering ・Recommended for food and cosmetic labels ・Has a semi-glossy coating on the surface with a smooth texture |

| Mirror Coat Paper | ・Commonly used for labels ・Glossy paper ・Recommended for promotional labels focusing on design ・Has a glossy coating on the surface with a smoother texture than art paper |

| Washi | ・Varieties include Taisho, Kiri, Housho, Unryu, Kusakizome, etc. ・Weak to water and low durability ・Recommended for labels on sake and sweets |

| Yupo (Synthetic Paper) | ・Film-like paper made mainly of synthetic resin ・Capable of withstanding a wide range of temperatures ・Recommended for labels on refrigerated and frozen foods and drinks ・Matte and has a smooth texture |

| PET (Transparent, White) | ・PET material, available in transparent and white, used for various purposes ・Suitable for highlighting printed areas or maintaining the material's transparency ・Glossy and has a smooth texture (semi-transparent types are also available) |

| PET (Gold, Silver) | ・PET film with aluminum deposition on the surface ・Has a high-end feel ・Excellent durability, water resistance, and heat resistance ・Available in glossy and matte types |

| Correction Paper | ・Paper processed with a gray back to prevent see-through ・Available in high-quality, coated, and synthetic paper (Yupo) |

| Thermal Paper | ・Thermal paper that blackens with heat for thermal printers ・Recommended for food quality labeling |

Here are some examples of products using these materials:

Art Paper

Art paper is a type of coated paper with high whiteness and gloss. It has excellent color rendering, making it suitable for beautifully expressing photos and illustrations.

Art paper is used for pamphlets, catalogs, photo books, and more. The image above is an example created by our company. For more details, please refer to the page below.

Case Study|Elgar Holdings LLC Food Labels

Yupo (Synthetic Paper)

Synthetic paper (Yupo paper) is a durable and water-resistant material. It is tear-resistant and used for labels on refrigerated and frozen foods and products in wet environments.

Yupo paper is environmentally friendly, as it does not release harmful substances when burned. The image above is an example created by our company. For more details, please refer to the page below.

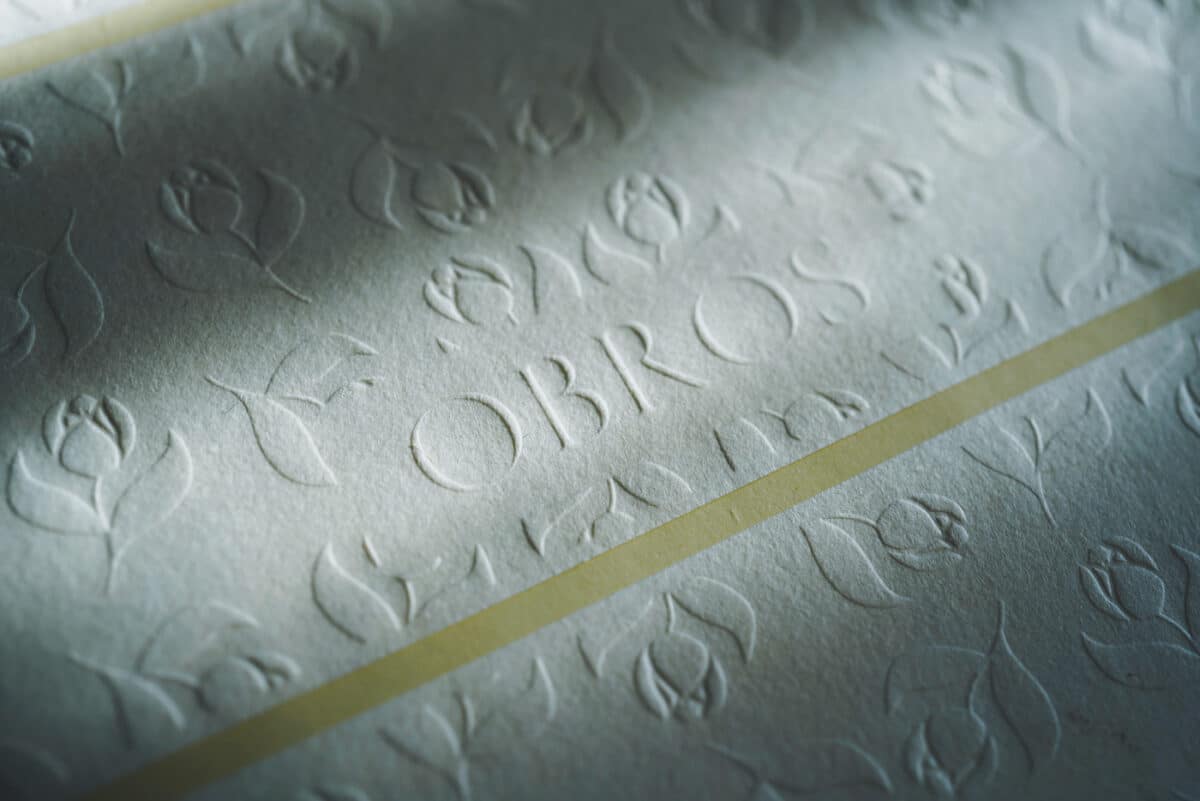

Washi

Washi, with its natural texture and unique feel, features a matte finish without gloss. There are various types, such as Taisho paper, cotton paper, which has a texture similar to Western paper.

The surface irregularities add depth to the design, creating a luxurious and calm atmosphere. Washi is often used for labels on sake, wine, and traditional Japanese sweets.

However, due to the fiber characteristics, Washi may experience ink peeling or color bleeding from friction. For more details, including the image above, please refer to the page below.

Case Study|OBROS COFFEE Product Seal

Adhesives for Product Labels

There are multiple types of adhesives for product labels, depending on the environment and purpose. Below is a summary of the main types of adhesives and their characteristics.

| Adhesive Type | Characteristics |

| General Adhesive | ・Can be used in a wide range of situations |

| Strong/Ultra-Strong Adhesive | ・Less likely to peel off compared to general adhesive |

| Releasable (Weak Adhesive) | ・Designed to be removed eventually ・Comes in various strengths even within releasable adhesives |

| Freezer-Grade Strong/Ultra-Strong Adhesive | ・Maintains adhesive strength even when cooled ・Suitable for use in refrigerators and freezers |

| Re-applicable | ・Used when you want to reapply a label that has been peeled off once |

For more details on adhesive types for labels, please refer to the article below.

Adhesion of Labels | Comprehensive Guide to the Optimal Adhesive Type for Your Business!

Processing for Product Labels

Various techniques are used for processing product labels, each with features that impact durability and design.

Below is a summary of the main processing techniques and their characteristics.

| Processing | Characteristics |

| Foil Stamping | ・A process where gold or silver foil is pressed ・Also available in color metallic, holographic, and pigment foils ・Suitable for adding luxury and impact |

| Varnish | ・Used to protect the design surface or change its texture ・Widely used for food labels |

| Embossing | ・A process that creates a raised design for logos or patterns ・Used to emphasize parts like logos or product names |

| Adhesive Neutralization | ・A process that removes adhesion by applying varnish or film to the adhesive side of the label ・Commonly used for promotional POP seals |

| Lamination (PP) | ・A film processing that protects the label and prevents color fading due to UV rays ・Can change the entire surface to a glossy or matte texture |

| Back Slit | ・Making slits in the backing paper of the label to make it easier to peel off ・Slits can be made at specified positions to serve as a guide when sticking |

When creating product labels, selecting the appropriate processing techniques according to the purpose can help differentiate your products from others.

Three Key Points to Know When Designing Product Labels

The design of product labels is essential to express the appeal and brand image of the product. Finally, we introduce the key points to keep in mind when designing product labels.

- Create attractive designs using color schemes, contrast, and fonts

- The impression changes depending on the material used

- Be aware of trends and current styles

Point 1: Create Attractive Designs Using Color Schemes, Contrast, and Fonts

For product labels, it is recommended to use three colors: base color, main color, and accent color. Using too many colors can make it difficult to balance the overall design.

Adding contrast is also important in design. Contrast creates emphasis, making it easier to intuitively convey product information. For example, enlarging or bolding elements like product names that you want to highlight can create visual impact.

Additionally, choose fonts that match the product. For instance, using a serif font for high-end products or Japanese-style products can effectively convey the product image.

Point 2: The Impression Changes Depending on the Material Used

Even when using the same color data, the image you get will differ depending on the material printed. For example, when using Washi, the ink absorption is good, resulting in darker and more subdued colors and patterns.

The image below shows a Washi seal we produced.

Special processing like foil stamping can further add a luxurious touch. Choosing the best material according to the design is crucial.

Point 3: Be Aware of Trends and Current Styles

Designing according to trends is crucial to appeal to modern consumers. Considering exposure on social media, creating attractive product labels that people want to share can be a key factor in encouraging consumers to pick up the product.

With the increasing awareness of environmental considerations, companies targeting eco-conscious markets are recommended to use eco-friendly labels.

Outdated label designs may not appear attractive to consumers and could result in the product being overlooked. It's important to create label designs that are both fresh and appealing.

Design Labels That Match the Product Image

Product labels play an essential role in conveying product information and image to consumers. While labels can be made at home, their functionality, feel, and durability may be inferior to those produced by a professional printing company.

On the other hand, labels created by printing companies are durable and have ink quality suited to the intended use, making them especially recommended when focusing on the finish.

As a specialized printing company for labels and seals, we produce a wide range of products as introduced in this article. If you are considering designing or creating product labels, please feel free to contact us below.

Start Your Project Now!

Contact Us or Get a Quote!