What Is Letterpress Printing? Advantages Explained

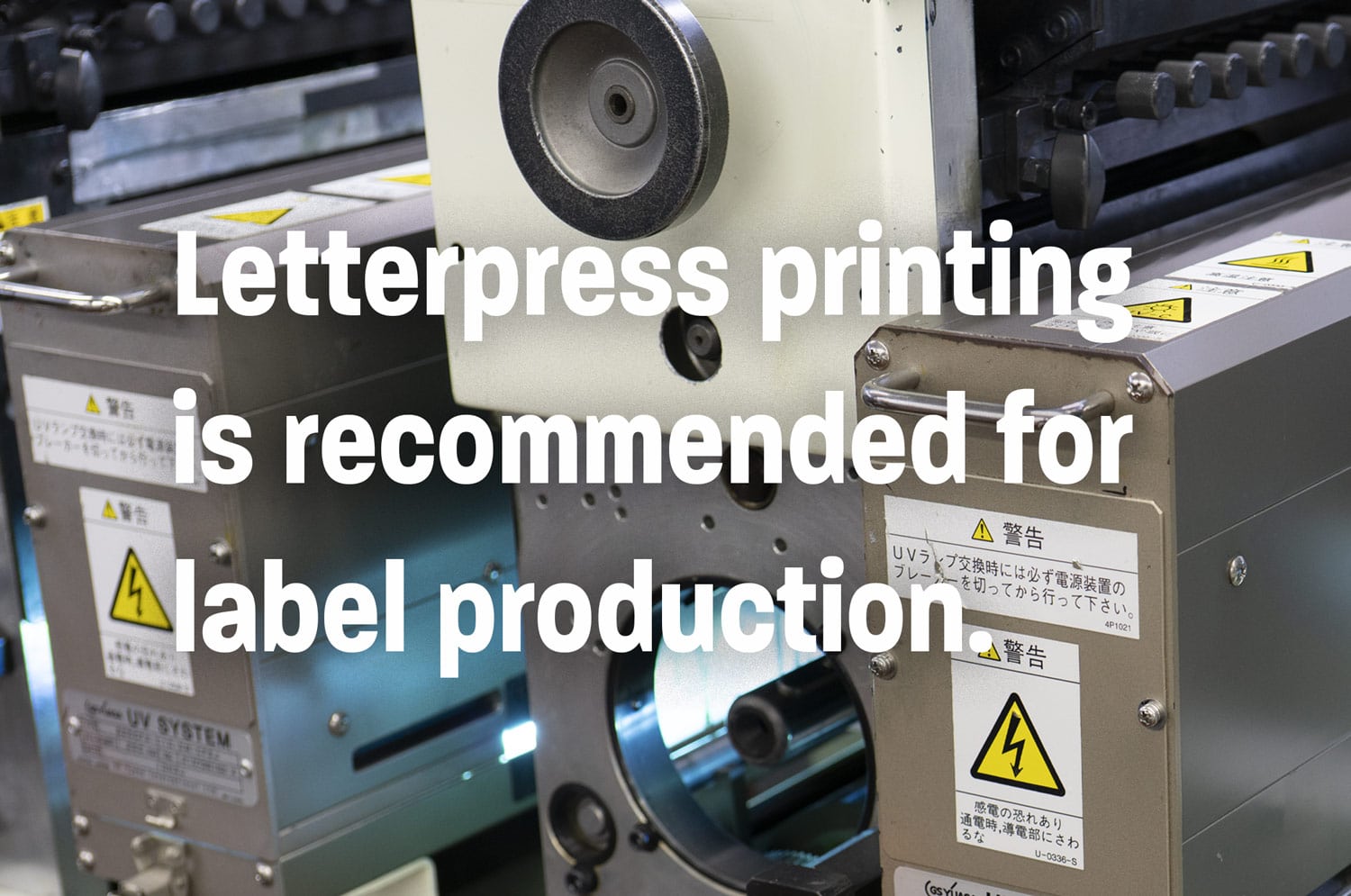

Letterpress printing for labels involves applying ink to the raised surface of a plate, making it a popular method in the label printing industry. This technique delivers clear results at a lower cost compared to other methods.

In fact, 95% of label and sticker production can be achieved using letterpress printing.

This article provides an overview of letterpress printing, its benefits and drawbacks compared to other methods, and showcases products made with this technique. If you’re considering letterpress for your product labels or stickers, this guide will be helpful.

As a specialized label printing company, we offer various printing methods. For any inquiries about label or sticker production, feel free to contact us.

Please feel free to contact us.

What Is Letterpress Printing? Explanation of its Mechanism and Features

Letterpress printing is a method where ink is applied to the raised portions of a plate and transferred to materials such as paper. Letterpress printing is a widely used technique in the label printing industry.

The Mechanism of Letterpress Printing

Letterpress printing requires the creation of a plate, which features raised areas for printing characters or designs, while the non-printing areas are recessed. Ink is applied to the raised areas and transferred to printing materials such as paper through a pressing process, similar to a stamp.

In the past, metal plates like zinc were commonly used. However, with advancements in printing technology, resin plates have now become the standard. These are often referred to as resin letterpress printing plates.

Features of Letterpress Printing

Letterpress Printing is characterized by clear and stable printing, making it particularly suitable for printing illustrations and text. Therefore, it is an ideal method for product label printing.

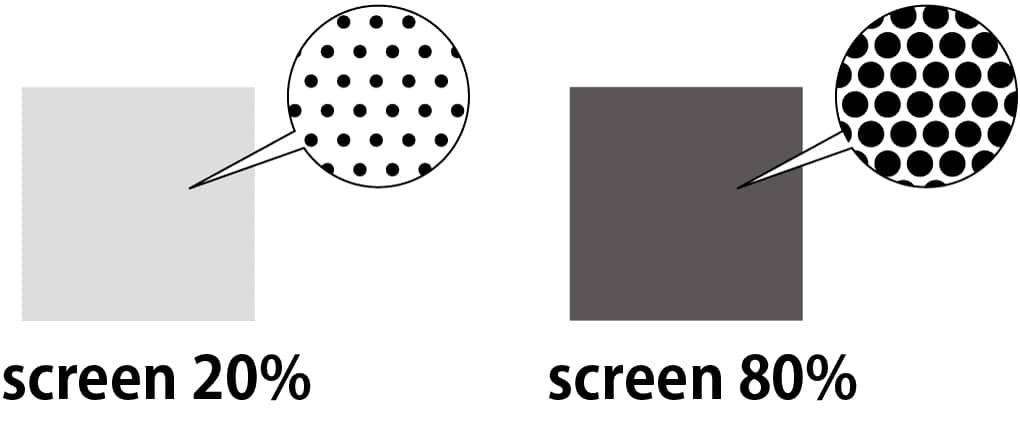

While it is slightly weaker in reproducing fine gradients compared to offset printing, which will be introduced later, it can still achieve gradients unless the color is extremely light. Gradients in Letterpress Printing are expressed through a collection of small dots called "halftone dots," with color density adjusted by the size and density of these dots.

・Small dots with low density → Light color

・Large dots with high density → Dark color

The Two Types of Letterpress Printing

There are two types: "flatbed" and "rotary." Each has different characteristics, so please refer to them as preliminary knowledge if you are planning to print labels. Note that the selection between flatbed and rotary is made by the printing company.

Type 1: Flatbed

The flatbed method involves setting a roll of paper and printing by pressing it onto a flat plate. In other words, the flat plate is pressed onto the paper for printing. One disadvantage is that the pressure may not be evenly distributed, leading to slight variations in printing, which may require some adjustments.

The flatbed method excels at printing simple designs with single colors, such as spot colors. It produces clear prints due to high printing pressure but is not ideal for reproducing shades. Additionally, it is slower, making it more suitable for medium to small print runs rather than large-scale printing. Despite its simple mechanism, it is highly versatile and convenient, capable of functions like foil stamping and embossing. While it was popularized in the Showa era, it is still widely used today and offers greater durability compared to on-demand printing.

Type 2: Rotary

The rotary method uses a rotating cylindrical plate for printing. The paper passes between cylindrical metal rollers for printing. In other words, the plate is formed into a cylinder that rolls while applying pressure for printing.

Since pressure is evenly applied, it allows for consistent printing, even on large areas. This method is ideal for "solid printing," where large areas are covered with ink, as well as high-precision photo printing. Achieving this level of stability is challenging for the flatbed method, which prints on a flat surface. In terms of speed, the rotary method is faster than the flatbed method, making it more suitable for large-scale printing.

The rotary method is widely used for printing labels with full-color designs and also supports spot colors like PANTONE or something.

Differences Between Letterpress Printing and Offset Printing

This section explains the differences between Letterpress printing and offset printing, both of which use plates for printing.

Offset printing uses a flat plate without any relief and relies on the repelling properties of water and oil.

When water is applied to the entire plate, the non-image areas, which are hydrophilic, attract water, while the image areas, which are oleophilic, repel water and attract ink. (While this concept is a bit complex, there's no need to delve deeply into it.) Offset printing can reproduce very fine details and is known for being one of the most precise printing methods available.

Detailed Differences Between Letterpress, Offset, and On-Demand Printing

There are three main types of printing used in label printing: Letterpress printing, offset printing, and on-demand printing. Below are the key differences and features of each method.

| Type | Letterpress Printing | Offset Printing | On-Demand Printing |

| Share | 85% of label printing companies have this (average equipment cost) | 10% of label printing companies have this (high equipment cost) | 5% of label printing companies have this (high running cost) |

| Mechanism | Uses a relief plate, ink is applied to raised areas and transferred to paper. | Uses a flat aluminum plate, utilizes the repelling properties of water and oil for printing. | Inkjet uses nozzles to spray ink, laser uses static electricity to transfer toner. |

| Features | Slightly weak in gradients | Capable of gradients | Capable of gradients |

| Spot Colors | Possible | Possible | Not possible |

| Cost | Average price | Expensive | Low cost for small runs, high cost for large runs |

| Lead Time | Short From 5 business days (excluding weekends and holidays) | Long From 10 business days (excluding weekends and holidays) | Short From 5 business days (excluding weekends and holidays) |

Below, we introduce the features of offset printing and on-demand printing in detail.

Offset Printing

As mentioned earlier, offset printing uses a flat aluminum plate without relief to apply ink, which is then transferred to a rubber roller before being printed onto paper. This method allows for high-volume printing in a short time, ensuring high-quality results with precise color matching.

Mainly used for producing books, magazines, and posters, offset printing is also used for label printing. Unlike Letterpress printing, offset printing can reproduce gradients and fine text. We use both Letterpress printing and offset printing depending on the design. However, offset printing tends to be more expensive than Letterpress printing, and the lead time increases by 4-5 days.

For more details on offset printing, please refer to the article below.

What Is Offset Printing? Process, Differences, and Uses

On-Demand Printing

On-demand printing refers to printing methods such as inkjet and laser printers that can be controlled by a PC. This relatively new printing method has gained popularity in label printing in recent years. Inkjet printing works by spraying ink from the tip of a nozzle, while laser printing uses static electricity to fix toner (a powdered pigment) onto paper.

Both methods handle gradients well. However, laser printing is clearer than inkjet printing, and inkjet tends to be slower in terms of printing speed, while laser printing is faster.

Both methods are suitable for small print runs but are not ideal for large volumes. This is because, unlike traditional printing machines that incur no additional costs after purchase, on-demand printing machines come with "high annual maintenance fees" and "counter charges (fees based on usage)" after purchase. The more you print, the higher the cost, making it unsuitable for large runs.

For more detailed information about on-demand printing, please refer to the article below.

What Is On-Demand Printing? Benefits and Considerations

As a specialized printing company for labels and stickers, we offer custom label creation services. If you consult with us, we will propose the most suitable printing method, so feel free to contact us.

The Two Advantages of Letterpress Printing

Letterpress Printing has the following advantages:

- Can print text clearly

- Low cost

Advantage 1: Clear Printing

Letterpress printing is capable of producing a wide range of designs, as demonstrated by its long-standing use in the label printing industry. While slightly less advanced than offset printing, it is more than sufficient for standard label and sticker printing. The print quality is better than inkjet and comparable to laser printing. Additionally, spot color printing is possible. Letterpress printing is also ideal for creating unique labels with options like metallic ink, varnish, and rough surface (rio-tone) inks.

Advantage 2: Low Cost

Another advantage of Letterpress printing is its low cost. Both the equipment and running costs are low, and the printing process is simple, making it more affordable than offset printing. If you need to produce 1,000 or more labels on a budget, Letterpress printing is recommended.

For specific ways to reduce the printing cost of labels, please refer to the article below. It explains practical methods from a professional perspective.

Cheap Sticker Printing Tips: How to Save on Your Orders

The Two Disadvantages of Letterpress Printing

The main disadvantages of using Letterpress printing are as follows:

- Not suitable for very small text or intricate designs

- Weak in gradient printing

Disadvantage 1: Not Suitable for Very Small Text or Intricate Designs

Letterpress printing is not ideal for very fine text or intricate patterns. Since ink is transferred by applying pressure, there is a risk that "small characters with many strokes" or "detailed designs" may become blurred. When working with small text or intricate designs, it's recommended to consult with the printing company during the design process.

Additionally, when pressure is applied to the paper with the plate, a double line may appear along the edges. While this is not very noticeable, some customers may find it bothersome. This is known as a "marginal" and is an inherent characteristic of Letterpress printing that cannot be avoided. If you wish to completely avoid this issue, it's best to choose offset printing or on-demand printing.

Disadvantage 2: Weak in Gradient Printing

Letterpress printing is not suitable for expressing gradients where color density changes in stages. This is because the color transition in the gradient is not smooth, and the boundary where the color changes becomes noticeable. Therefore, even if the estimate is for Letterpress printing, if the submitted data includes gradients, a switch to offset printing may be necessary. It’s recommended to provide the data at the time of the estimate for the most accurate quote.

Even if you choose Letterpress printing for its cost-effectiveness, if gradients are included, you might need to switch to the more expensive offset printing, so it's important to consider this. However, if you do not have a particular preference for gradients, Letterpress printing should suffice.

※Recently, plate technology has significantly improved, and printing accuracy for gradients has increased. In many cases, the quality is now so high that it can be mistaken for offset printing, so the limitations with gradients are becoming less of a concern.

If you are considering printing product labels or stickers and are unsure about the most suitable printing method, please feel free to contact us. We will propose the best method for you.

Introducing Production Examples Using Letterpress Printing

Finally, we introduce production examples using Letterpress Printing from our company. If you are considering using Letterpress Printing for product labels or stickers, please refer to these examples.

Example 1: Minabe Craft Umeshu Label

We created this label using Letterpress Printing with three colors on washi cotton material. The product name is "Yii," featuring a pop design that does not resemble traditional umeshu labels.

For more details about this colorful and fun product label that breaks the conventional image of umeshu, please see the page below.

Example: Minabe Craft Umeshu Label

Example 2: Hokusai Samurai Hologram Sticker

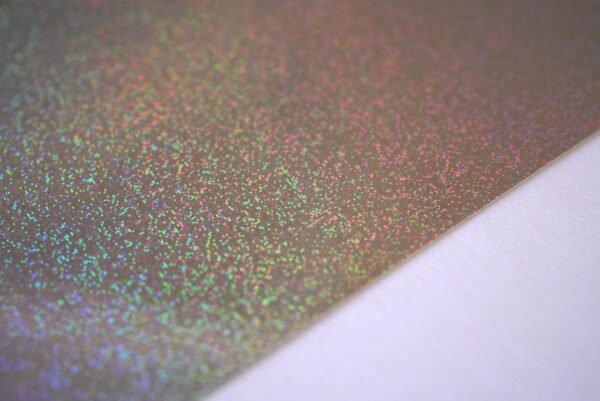

We created a hologram sticker for the Sumida Hokusai Museum's special exhibition "Hokusai Samurai Painting." The design features a brave samurai in a scene as if snow is dancing around.

We used "Hologram NO.3" as shown in the image below, and the sticker was printed using Letterpress Printing with three colors: white, spot color, and black.

For more details about this sticker, please visit the case study page.

Example: Sumida Hokusai Museum Special Exhibition "Hokusai Samurai Painting" Hologram Sticker

Example 3: Blue Bottle Coffee Label

We created package labels for Blue Bottle Coffee Japan LLC. The labels are made of high-quality paper with a smooth texture. The labels were printed using Letterpress printing with three spot colors, followed by embossing to create a raised design.

For more details about this work, please see the page below.

Example: Blue Bottle Coffee Label

If You Want Clear Printing at a Lower Cost, Letterpress Printing is Recommended

Letterpress printing applies ink to the raised parts of a plate and transfers it to paper, similar to a stamp. By applying ink to the raised areas and pressing, it ensures clear text reproduction.

In addition, compared to other printing methods, Letterpress printing offers cost-saving advantages, making it an ideal choice for those looking to produce materials while keeping costs low.

As a specialized label printing company, we offer a wide range of printing methods, including Letterpress printing, flat printing, and intaglio printing. If you are looking to create product labels or stickers, please feel free to consult with us using the link below.

Start Your Project Now!

Contact Us or Get a Quote!