Satin Stickers Features and Benefits

Satin seals are unique for their fabric-like texture and resistance to peeling when applied to clothing. Learn about their features, production methods, and materials in this guide. Contact us for custom-made satin seals, perfect for clothing and even perfume bottle labels.

For those struggling with label and sticker printing

Wondering if this kind of printing is possible? Or how much budget is needed?

If you have any concerns, feel free to reach out to us.

First, check out our case studies.

※Orders are available starting from 1,000 pieces.

※Business hours: Japan Standard Time, Monday to Friday, 9:00 AM - 5:00 PM

What Are Satin Stickers? Key Features Explained

Satin stickers are labels that can be applied to clothing and fabrics such as T-shirts, shirts, and jackets. They are also known as "acetate satin" or "fabric stickers."

Made from a fabric-like material, satin stickers blend more easily with the fabric compared to regular stickers, ensuring a secure attachment. As a result, they are highly durable and resistant to peeling even after extended use.

Due to their glossy appearance, satin stickers are ideal for adding a touch of elegance or luxury. They can be customized into various shapes such as ovals or squares, making them perfect for those who value originality in their designs.

Satin Sticker Applications

Satin stickers are made from acetate, a synthetic fiber, which allows them to adhere easily to fabric and minimizes adhesive residue when removed.

Despite being fabric-based, they offer high-quality printing, making them suitable for a wide range of applications.

Here are some of the primary uses of satin stickers:

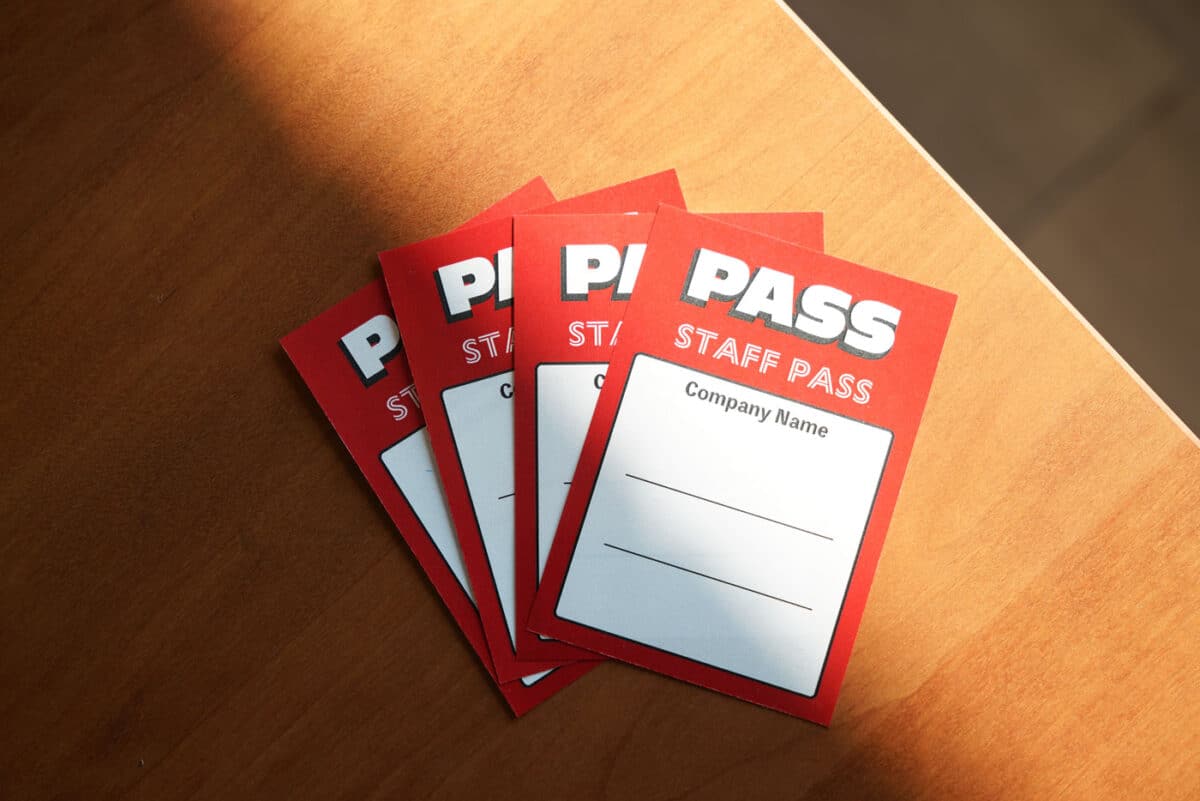

- Event and Live Staff Stickers: Used to identify staff members at events or live performances.

- Bib Number Stickers: Commonly used in races or competitions to display participant numbers.

- Exhibition Entry Stickers: Used as entry passes for exhibitions or trade shows.

- Guest Passes: Provided to guests as a way to access exclusive areas or events.

- Name Stickers: Ideal for personalizing items with names, often used in educational or family settings.

- Tour Travel Participant Badges: Used to identify members of a tour group.

- Stickers for Children: Fun and safe stickers designed for young children, often used for learning or decoration.

- Product Labels (e.g., Perfume Bottle Labels): Perfect for high-end product labeling, such as on perfume bottles or luxury goods.

Given their characteristics, satin stickers are perfect for use at events lasting from a few hours to a day, such as event staff identification, access management, and distribution to participants. Additionally, when used as product labels on items like perfume bottles, they can enhance the sense of luxury and originality.

Benefits of Satin Stickers

Satin stickers offer three main benefits:

- No Safety Pin Needed, Can Be Directly Applied to Fabric: Satin stickers can be easily applied directly to fabric without the need for a safety pin.

- Durable and Resistant to Peeling: Even when applied to clothing, satin stickers are highly durable and resistant to peeling.

- Writable with Pen: You can write on satin stickers with a pen, making them perfect for adding names, dates, or other personal information.

By understanding these benefits, you can make more effective use of satin stickers.

Benefit 1: No Safety Pin Needed, Can Be Directly Applied to Fabric

Satin stickers can be directly applied to fabric without the need for safety pins. This feature makes them particularly useful and safe for children's events and sports competitions.

When using safety pins or clips, there is a risk of puncturing the fabric, but with satin stickers, this concern is eliminated.

Additionally, they can be easily applied without the need for tools like needles, thread, or irons. As a sticker, they are quick and convenient to apply, making them ideal for busy environments or situations where large quantities are needed.

Benefit 2: Durable and Resistant to Peeling on Clothing

Although satin stickers are not stretchy, they adhere firmly to fabric without the rigidity of paper or film stickers. Their ability to blend seamlessly with clothing and fabric makes them comfortable to wear, even during daily activities or physical exertion.

Thanks to their strong adhesion, satin stickers are widely used in sports events for bib numbers and staff name tags, where reliability is essential.

Benefit 3: Writable with Pen for Customization

Satin stickers can be written on directly with a pen, making them ideal for adding names, dates, or other custom markings. For instance, they can be used as name labels for children's clothing, allowing for easy personalization.

In events and sports competitions, satin stickers provide the flexibility to write participant names, bib numbers, dates, and other information, making them versatile in various situations. This convenient feature allows for quick additions of details, especially when printed materials alone may not suffice.

How Satin Stickers Are Made

Due to the unique properties of satin stickers, it is recommended to have them produced by a professional printing company.

The reason for this is that high-quality results are difficult to achieve with home printers. Satin stickers are made from fabric-like materials, which can cause ink to smudge easily with home printers, leading to unstable results. While it is possible to purchase pre-made satin sticker labels and print them at home, using pigment ink is necessary to achieve proper color adhesion.

For custom designs, especially for logos or product labels, relying on a printing company is the best choice for a professional and reliable outcome. Satin stickers are typically printed using letterpress or offset printing methods, each with its own unique advantages.

| Letter Press | Suitable for Simple Designs with 1 to 3 Colors |

| Offset printing | ・Capable of Printing Designs with 4 or More Colors, Gradients, and Shading Effects ・Primarily Produced in Large Quantities ・Small Orders May Be Challenging, So It’s Important to Consult with the Printing Company in Advance |

印刷会社では、用途やデザインに応じて最適な印刷方法を選択し、高品質な仕上がりを実現できます。

Satin Sticker Materials and Adhesives

In this section, we will introduce the materials and adhesives (adhesive agents) used in satin stickers.

By understanding the characteristics of each, you can make the most appropriate choice based on the specific use case or purpose. Let’s take a closer look.

Satin Sticker Materials

Satin stickers are primarily made from a material called "Satin Tack." Satin Tack is a flexible material that blends easily with fabrics, making it ideal for use on clothing.

The white satin tack has a glossy finish similar to silk, adding a touch of luxury. The surface has a smooth texture, giving a sophisticated and refined impression.

Since it falls into the higher price range among film materials, it is perfect for applications where a sense of exclusivity is desired. To reduce costs, you can keep the color count and size modest while increasing the quantity to lower the unit price.

However, satin tack is absorbent, so there is a risk of ink smudging, especially in rainy or humid environments. Therefore, for outdoor events, it’s recommended to apply a varnish finish.

Additionally, due to its absorbency, ink color may bleed during printing. It’s advisable to conduct a color proofing test in advance to confirm the final output.

For those who want to learn more about satin sticker materials, please refer to the next article.

Satin is a material that can be applied to clothing.

Satin Sticker Adhesive

Satin stickers use a textile adhesive, which provides excellent adhesion to fabrics and ensures ease of use.

The textile solvent adhesive used in satin stickers is firmer and more durable compared to standard adhesives. This makes it adhere strongly to fabric and other textile materials, preventing peeling and ensuring stable use.

Additionally, when removing satin stickers, there is minimal adhesive residue, and the marks are less noticeable, so there is little risk of damaging the fabric or clothing.

However, satin stickers lose their adhesive strength when washed, so they are generally designed for single-use. Therefore, they are not suitable for clothing or fabrics that require frequent washing.

Precautions When Using Satin Stickers

Satin stickers are convenient as they can be applied to fabric, but there are a few important precautions to keep in mind when using them.

Here are three key points to be particularly careful about:

- Susceptible to Friction: Satin stickers can wear down or peel off more easily with frequent friction.

- Risk of Adhesive Residue on Some Materials: Depending on the material you apply them to, there may be a risk of adhesive residue remaining after removal.

- Visible White Edges Around the Cut Line: In some cases, the white edges of the cut line may be noticeable, affecting the appearance of the sticker.

Precaution 1: Susceptible to Friction

Satin stickers are susceptible to friction. The glossy surface, in particular, can wear down, causing the design or printed areas to fade or peel off more easily. This is why it’s important to be mindful of where they are applied.

For instance, applying them to areas that are frequently touched or rubbed may lead to a decline in the sticker’s appearance and functionality. It’s recommended to use satin stickers in places with little friction, such as on bib numbers or staff passes, which are typically for one-time use.

By using them in the right environment, you can maintain both the beauty and functionality of satin stickers.

Precaution 2: Risk of Adhesive Residue on Some Materials

While satin stickers are generally designed to leave minimal adhesive residue when removed, certain materials may still leave behind adhesive or potentially get damaged.

Particular attention is needed with the following two materials:

| Long-Pile Fabrics | ・Applying to Wool or Fleece Fabrics: If satin stickers are applied to wool or brushed fabrics, there may be adhesive residue left behind when removed. ・Potential Fiber Pulling: In some cases, satin stickers may pull fibers from the fabric when removed. |

| Leather Products (Suede) | Leather May Retain Adhesive: Satin stickers may leave adhesive residue on leather. Potential Impact on Appearance or Damage: They may affect the appearance or damage the material. Avoid Using on High-End Leather Products: It is recommended to avoid using satin stickers on luxury leather items. |

It is recommended to perform a test on an inconspicuous area before using satin stickers on long-pile fabrics or leather products. This test will allow you to check for adhesive residue or any potential effects on the material in advance.

Precaution 3: Visible White Edges Around the Cut Line

Satin stickers may show white edges at the cut line, especially when the design is printed in dark colors. The white cut edges can become more noticeable in these cases, so it’s important to be cautious.

Situations where the white cut edges are more likely to be visible include:

- When the Sticker Size is Small

- When the Cut Shape is Complex

To improve the quality of the finished product, it is recommended to consult with the printing company in advance. Adjusting the design to a simpler shape or confirming the final result can help. By requesting a prototype, you can review the appearance of the finished product before it’s completed.

Learn the Features and Create Satin Stickers

Satin stickers are designed to adhere to fabric, making them perfect for applications like event staff identification or bib numbers for sports events. They blend easily with clothing and are resistant to peeling, making them useful in various situations.

However, satin stickers are susceptible to friction, and depending on the material they are applied to, adhesive residue may remain. To create the most suitable satin stickers, it is important to understand the characteristics of the materials and adhesives, and ensure the stickers are produced to match their intended use.

At our company, we produce a wide range of product labels and stickers, including satin stickers, tailored to your specific needs. While custom designs like the ones mentioned above may incur additional costs, we are fully equipped to handle the production. Of course, we also provide thorough support in selecting the appropriate materials and adhesives. If you're facing challenges in creating product labels, feel free to consult with us.

Start Your Project Now!

Contact Us or Get a Quote!