What is Roll Sticker Printing? Benefits, Costs, and Specifications

When ordering commercial stickers, you can choose your preferred delivery format to suit your requirements. Among these, roll sticker printing is one of the most popular sticker formats. It is ideal for applications where the stickers need to be applied, and is used in a wide range of settings including factories and retail stores.

We are a printing company specializing in sticker production. From standard delivery formats such as roll sticker printing to specialized shapes, we produce a wide variety of stickers. If you are considering commercial or custom sticker production, please feel free to contact us.

For those struggling with label and sticker printing

Wondering if this kind of printing is possible? Or how much budget is needed?

If you have any concerns, feel free to reach out to us.

First, check out our case studies.

※Orders are available starting from 1,000 pieces.

※Business hours: Japan Standard Time, Monday to Friday, 9:00 AM - 5:00 PM

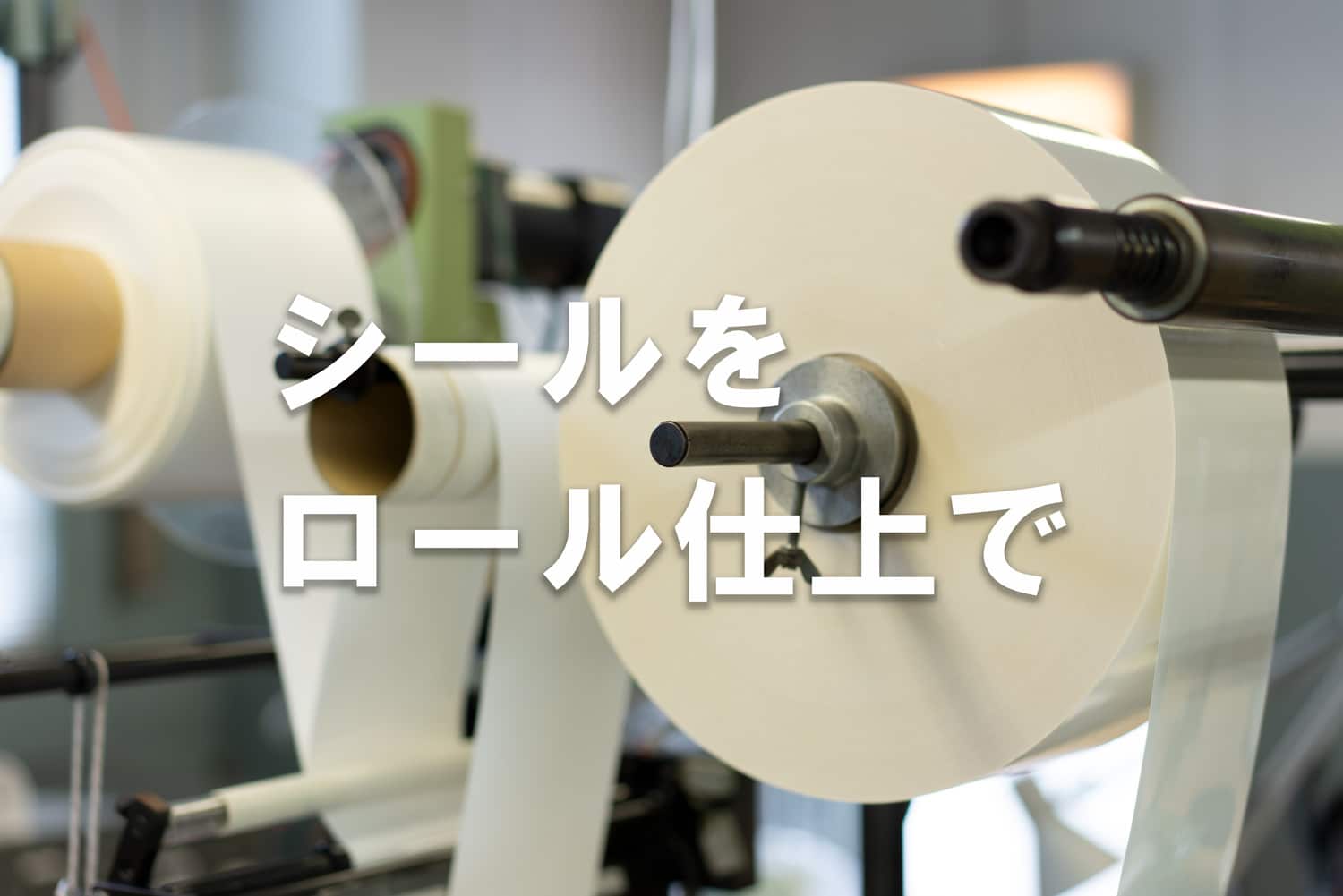

What is Roll Sticker Printing?

Roll sticker printing, also known as roll finishing, refers to commercial stickers delivered in a roll. The stickers are continuously attached to a long, sheet-like backing. Because they are suitable for automatic application using a labeller, they are often chosen to reduce the labor involved in sticker application.

In addition, they can be stored hanging, which saves space. This delivery format is as popular as standard sheet cuts and is used in a wide range of applications.

Advantages of Choosing Roll Sticker Printing

The situations in which roll sticker printing is ideal are as follows:

- Easy storage

- Smooth application process

- Compatible with labellers

Advantage 1: Easy Storage

Roll stickers take up less space than sheet stickers, making them suitable for environments with limited storage. Increasing the number of labels per roll also prevents large bundles of loose stickers.

If you want to stock a large number of stickers while minimizing space, roll sticker printing is highly recommended.

Advantage 2: Smooth Application Process

For stickers that require application, such as product labels or ingredient display stickers, roll sticker printing is ideal. In the case of sheet stickers, manual application is necessary, which reduces efficiency and takes more time.

On the other hand, using a manual labeller allows for faster and more accurate application compared to manual stickering. As a general guideline, if you need more than 3,000 stickers, it is recommended to opt for roll sticker printing and use an automatic labeller rather than a manual one.

Advantage 3: Compatible with Labellers

When using a labeller, it is necessary to order stickers in roll form. A labeller is a machine that automatically applies stickers to the target surface.

Below, we introduce one of our projects for craft beer cans.

Roll sticker printing offers the convenience of streamlining the application process. The fact that it can be set up for labellers is a significant advantage; however, when ordering, it is important to verify the diameter of the paper tube. If the size differs, it may not be compatible with the machine, so careful ordering is essential.

Other delivery formats available in addition to roll sticker printing are as follows:

Sticker Delivery Formats to Suit Different Applications

Products and Materials Suited for Roll Sticker Printing

Roll sticker printing can be applied to stickers made from a wide range of materials, whether paper or film. For paper-based stickers, you can choose from high-quality paper or coated paper, and for film-based stickers, standard materials such as Yupo or PP are typically available in roll form.

Below, we showcase one of our projects for beer labels.

Since the labels are applied to bottles using machinery, they were finished in roll form. They are made of water-resistant Yupo 80μ with gold foil stamping.

When combined with a laminate finish on film materials, you can produce stickers with high water resistance and durability. By choosing high-adhesion or refrigerated/freezing adhesives according to the application, you can also enhance the functionality of the stickers. Since the details of the materials offered vary by printing company, it is advisable to consult during the planning stage to ensure a smooth production process.

We are a printing company specializing in stickers, and we offer a wide variety of sticker types. Please feel free to contact us via “Contact Us” for any inquiries.

Shapes Available for Roll Sticker Printing

Since roll sticker printing is often used for product labels applied by labellers, the standard shape is a rectangle. Although we can accommodate stickers of various shapes, be cautious with pointed shapes as they may become deformed upon peeling.

If you wish to reduce processing costs, it is effective to minimize the gap between stickers to maximize the number of stickers per roll. For example, with the same total of 10,000 stickers, “500 stickers x 20 rolls” is more expensive than “2,500 stickers x 4 rolls.” Additionally, for non-standard shapes, costs tend to be slightly higher compared to rectangular shapes.

Even a small cost difference per unit can add up significantly when ordering in large quantities. When placing large orders, it is important to choose the shape carefully in advance.

Specifications Available with Roll Sticker Printing

When ordering roll sticker printing, there are several specifications that you need to choose from.

- Inside roll or outside roll

- Sticker dispensing direction

- Inner diameter size of the paper tube

Specification 1: Inside Roll vs. Outside Roll

In roll sticker printing, you can choose between an inside roll type, where the stickers are attached to the inside of the roll, and an outside roll type, where they are attached to the outside. Generally, the outside roll type is more common.

Specification 2: Sticker Dispensing Direction

You can also specify the direction in which the stickers are dispensed when they are pulled out. Options include right-side, left-side, head-first, and tail-first. When choosing the dispensing direction, consider factors such as the compatibility with your labeller, ease of peeling, and application efficiency.

Specification 3: Inner Diameter Size of the Paper Tube

When using a labeller, it is important to confirm the inner diameter size of the paper tube before placing an order.

If the size is incorrect, the roll may need to be re-wound, so it is essential to double-check before making a formal order. For first-time orders in roll form, it is advisable to attach the labeller’s specification sheet to your order, so that the production is tailored to the machine’s requirements.

The following are the common paper tube sizes (inner diameters) used with labellers and sticker peelers:

- 76.2 mm (3 inches) ← Used by 99% of labelling machines

- 38.1 mm (1.5 inches) ← Used for sticker peelers

- 25.4 mm (1 inch) ← Used for sticker peelers

*Labeller: A machine that applies labels to items such as bottles

*Sticker Peeler: A device that dispenses stickers one at a time

The above are just examples; it is important to check the type and size of your machine when placing an order.

Cost Estimates for Roll Sticker Printing

This section explains the cost estimates when ordering roll sticker printing.

If you are looking for a low-cost option, we recommend our “appropriate quantity roll finish.” By maximizing the number of labels per roll, processing costs can be reduced. It is useful to provide the maximum roll diameter when ordering. By ensuring the roll does not exceed this diameter, your operators will need to change rolls less frequently.

Conversely, if the number of stickers per roll is low, processing costs will increase. For example, for 1,000 stickers, one roll of 1,000 stickers is cheaper than 10 rolls of 100 stickers each. To maximize cost performance, it is recommended to order at least the minimum quantity.

Simplify Your Application Process with Roll Sticker Printing

Roll stickers are stickers that have been printed and then wound onto a paper tube for delivery. They are especially advantageous when handling stickers that require application. Also, if you wish to use a labeller, roll sticker printing is the only option available, so it is important to verify the specifications of your labeller before ordering.

We are a printing company that produces stickers in a variety of delivery formats. In addition to roll sticker printing, we also produce other types of labels for commercial use. If you are considering sticker production, please feel free to contact us.

Start Your Project Now!

Contact Us or Get a Quote!