What is "Nori-Goroshi"? Features, Processing Methods, and Recommended Materials

Norigoroshi is a processing technique used in products such as POP-up seals and attention seals. Many may wish to learn the basics when considering production using Norigoroshi processing.

In this article, we introduce everything from the characteristics of Norigoroshi processing to recommended materials and case studies. If you are considering producing products that incorporate Norigoroshi processing, please use this as a reference.

As a printing company specializing in labels and seals, we offer a variety of seals including attention seals. If you are experiencing difficulties with label or seal production, please feel free to contact us using the link below.

For those struggling with label and sticker printing

Wondering if this kind of printing is possible? Or how much budget is needed?

If you have any concerns, feel free to reach out to us.

First, check out our case studies.

※Orders are available starting from 1,000 pieces.

※Business hours: Japan Standard Time, Monday to Friday, 9:00 AM - 5:00 PM

What is Norigoroshi? Characteristics of the Process

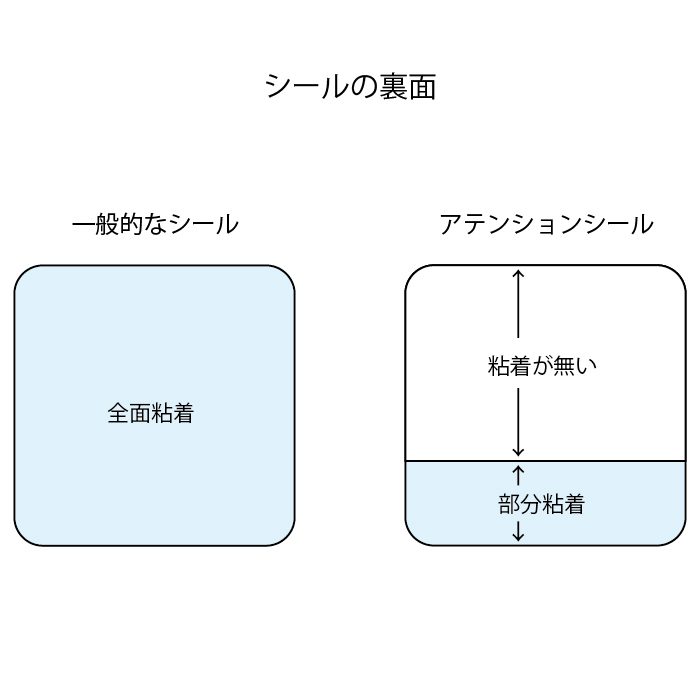

Norigoroshi (norigoroshi) refers to a process that eliminates the adhesive function of seals and labels (i.e., “killing” the adhesive properties). Seals processed in this way differ from conventional seals in that the adhesive is only partially applied on the back.

Norigoroshi processing offers multiple applications and can be utilized in various scenarios with some ingenuity.

Three Main Applications of Norigoroshi Processing

The main applications for seals processed with Norigoroshi are as follows:

- Effectively promote products

- Make seals easier to peel off

- Make perforations easier to cut

Application 1: Effectively Promote Products

The most common use of Norigoroshi processing is for attention seals (POP seals).

An attention seal refers to a label affixed in such a way that part of it protrudes from the product package. When applied to stand out, the seal is more noticeable on shelves, making it effective for visual appeal.

If a conventional seal is used as an attention seal, the adhesive is applied over the entire surface, which can lead to dust accumulation or the seal sticking to other products. However, with Norigoroshi processing, only part of the seal remains adhesive, preventing these issues.

Attention seals processed with Norigoroshi further enhance the product’s appeal.

Application 2: Make Seals Easier to Peel Off

Norigoroshi processing is also used to make seals and labels easier to remove.

Typically, low-tack or re-peelable adhesives are used to facilitate removal, yet without an initiating point, the seal may still be difficult to peel off.

By applying Norigoroshi processing, a removal-friendly point can be created.

For example, by processing a portion of the seal with Norigoroshi to eliminate its adhesiveness and creating a triangular area that is easy to grasp with your fingertips, the seal can be easily peeled off.

Application 3: Make Perforations Easier to Cut

Norigoroshi processing is also effective for seals with perforations.

Seals with perforations have fine cuts to facilitate tearing or folding, but if adhesive covers the entire surface, clean cutting becomes difficult.

Thus, by applying Norigoroshi processing to the back of the perforated area, a non-adhesive section is created, making the seal easier to cut neatly. This processing method is effective in enhancing the usability of perforated seals.

Norigoroshi Processing Methods

There are mainly two methods for Norigoroshi processing.

- Varnish Coating

- Film Application

Method 1: Varnish Coating

Varnish coating is a method that applies a special varnish to the adhesive surface to neutralize its stickiness.

The advantage of varnish coating is that it allows for free design of the non-adhesive area and shape, making it suitable for a wide range of applications such as attention seals.

However, since the coating reduces the adhesive strength, there is a possibility that the adhesive may partially recover over time, so caution is necessary.

Additionally, varnish coating is sometimes unsuitable for transparent materials because the varnish is not opaque, which can reduce the material’s transparency.

Method 2: Film Application

Film application is a method where a special film is applied to the adhesive surface of a seal to render it non-adhesive. Similar to varnish, it can be applied partially to reduce adhesion.

Since the film, once applied, does not recover its adhesive properties over time, film application is ideal for product seals that will be displayed for extended periods.

Additionally, aside from Norigoroshi processing, there is also a method called “partial adhesive liner” for creating a non-adhesive area on part of a seal.

In the next section, we will explore the differences between Norigoroshi processing and partial adhesive liner.

Differences Between Norigoroshi Processing and Partial Adhesive Liner

When producing attention seals, in addition to Norigoroshi processing, there is also a method that uses a “partial adhesive liner”.

Both methods create a non-adhesive area on a portion of the seal and achieve the same effect, though their production methods differ as follows:

| Norigoroshi | A processing method that uses varnish or film on the adhesive surface of the seal to reduce its stickiness. |

| Partial Adhesive Liner | A method that employs specially processed liner rolls custom-made by the manufacturer for the adhesive surface. |

Partial adhesive liner is a method where specially processed liner rolls are custom-manufactured. The liner is supplied in a partially non-adhesive state, enabling mass production of seals with non-adhesive portions.

However, because the custom liner is produced prior to the printing process, it is necessary to consult in advance regarding delivery times. Moreover, since the non-adhesive area is limited to straight lines, design flexibility is restricted.

Choose either Norigoroshi processing or partial adhesive liner according to the intended use and purpose of the seals you are producing.

4 Recommended Materials for Norigoroshi

When applying Norigoroshi processing to seals, selecting the right material is also important.

Especially for attention seals, it is crucial to choose a material in which the non-adhesive areas do not crease or bend.

The materials suitable for Norigoroshi processing are the following four:

- Yupo

- Silver Namer

- Transparent PET

- Art Coated Paper

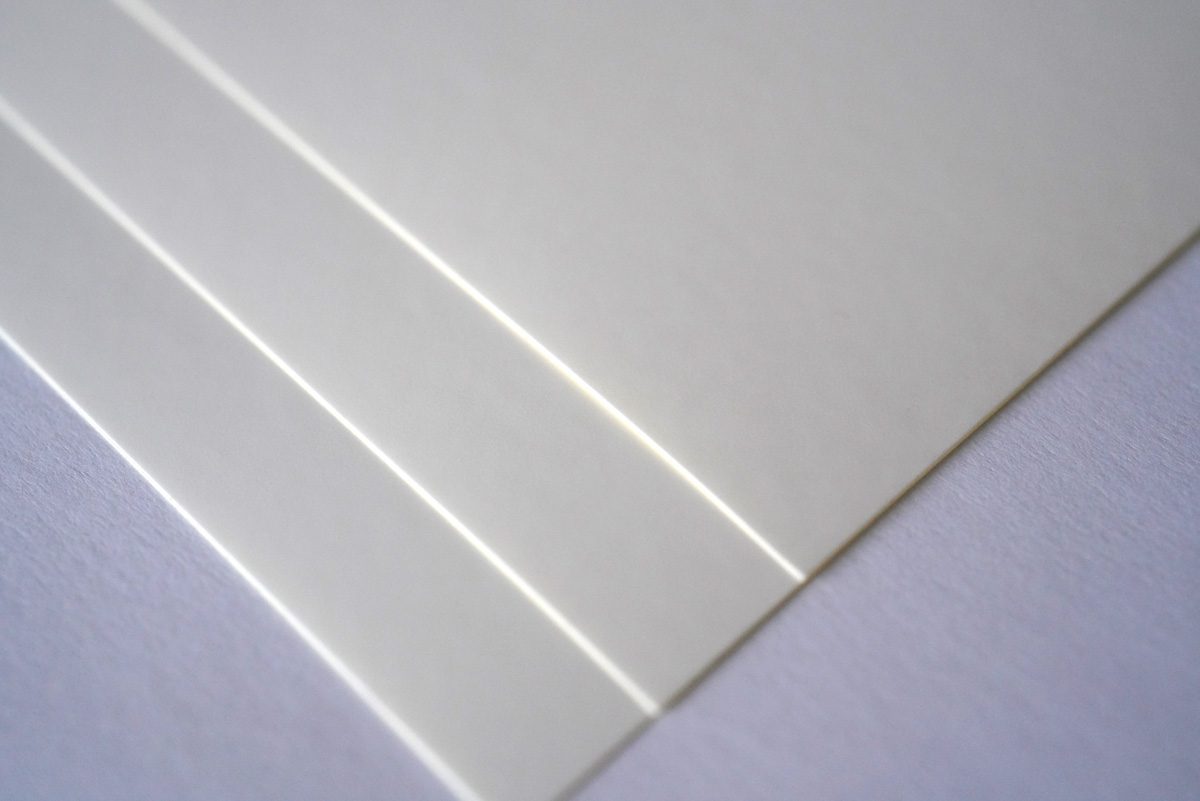

Recommended Material 1: Yupo

Yupo is a material primarily made from polypropylene, known for its durability and water resistance. As such, it is used in products like frozen foods and cosmetics that may be exposed to moisture or water.

It is also resistant to oils and chemicals, so its quality hardly deteriorates even upon contact. Yupo has a smooth, slick texture and is cost-effective, making it widely used.

For more detailed information about Yupo, please refer to the article below.

Label Material|Yupo is a cost-effective film material that boasts high durability.

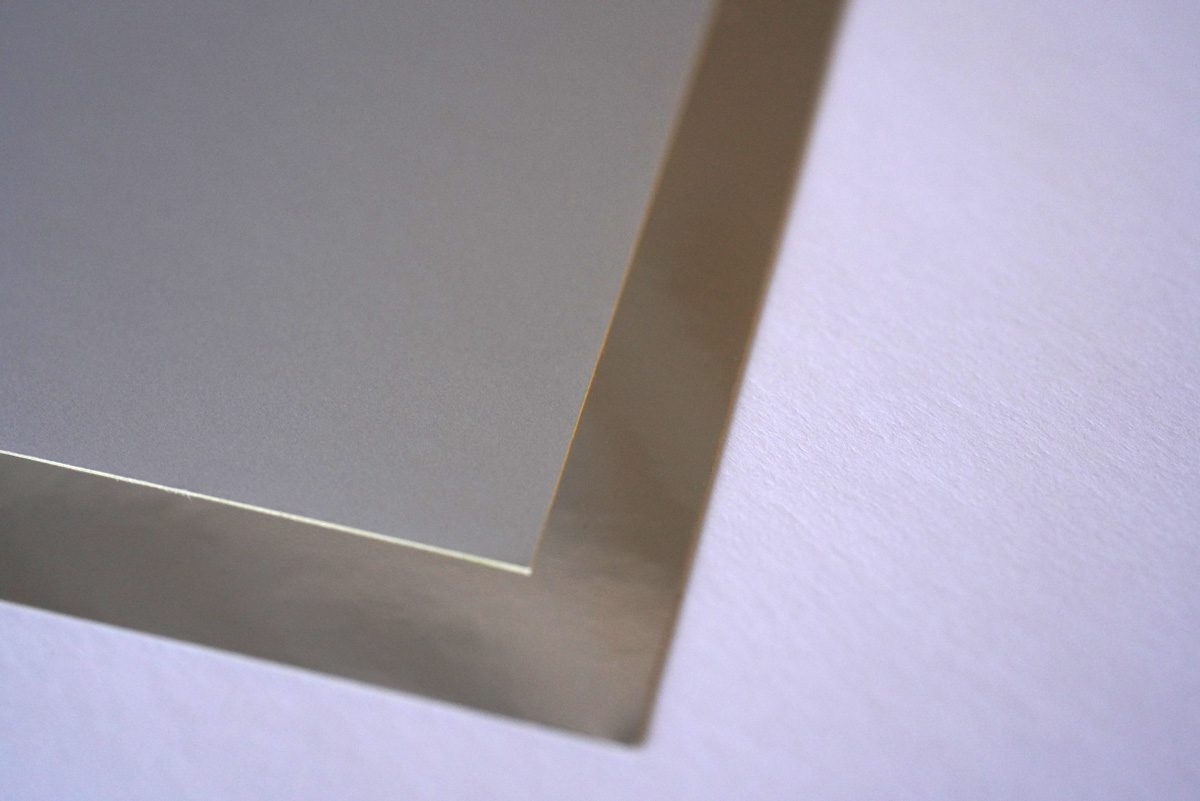

Recommended Material 2: Silver Namer

If you want your product to stand out even more, Silver Namer (Silver PET) is recommended.

Silver Namer is characterized by its silver metallic finish, which reflects light to accentuate the product’s presence. Additionally, as a film material, it allows for clean removal of seals.

It is also excellent in durability and water resistance, making it suitable for long-term use. Silver Namer is available in two types: Gloss and Matte. The Gloss type has a smooth feel, while the Matte type has a more textured feel.

It is best to choose according to the image of your product.

For more details about Silver Namer, please refer to the following article.

Label Material|Silver Namer is a film material available in both Gloss and Matte finishes.

Recommended Material 3: Transparent PET

Transparent PET is recommended for those who wish to apply Norigoroshi processing to transparent seals.

Because it is transparent, it is ideal for producing attention seals or POP seals that take advantage of a see-through effect. Transparent PET is available in a glossy type with a smooth, slick feel, and a matte type with a more textured feel.

Also, when producing seals with a transparent material, printing the design after priming with white ink will make the design stand out even more clearly.

For more detailed information on Transparent PET, please refer to the article below.

Recommended Material 4: Art Coated Paper

Art Coated Paper is especially recommended when you want to reduce costs.

However, when using Art Coated Paper, please note the following two points.

- It may not peel off cleanly

- The paper may curl due to moisture absorption

Because Art Coated Paper may not peel off neatly, it is necessary to consider using low-tack or re-peelable adhesives. In addition, since the paper can curl when it absorbs moisture, adjustments such as changing the size of the seal or increasing the adhesive area may be required.

We offer material samples at our company. If you are unsure about material selection, you can try applying the sample to an actual product to check its usability. Please feel free to contact us.

Important Points for Norigoroshi Processed Seals

The main considerations for Norigoroshi processing are the following two:

- Longer lead times may be required

- It is more costly compared to conventional seals

Note 1: Longer Lead Times May Be Required

Norigoroshi processing involves additional steps such as applying varnish or film, which increases the overall production process compared to conventional seal production.

Furthermore, in addition to the normal printing process, one extra plate dedicated to Norigoroshi processing must be created. This can result in longer production times compared to regular seals.

When ordering seal production, it is important to plan with sufficient lead time.

Note 2: It Is More Costly Compared to Conventional Seals

Since Norigoroshi processing involves more steps and the creation of an extra dedicated plate, production costs are higher. Therefore, it is recommended to request a quote from the printing company beforehand.

To obtain a more accurate quote, please provide the following information:

- Seal size

- Shape

- Usage

- Quantity

- Design concept

If you have any concerns about the material or processing, please do not hesitate to consult with the printing company. Our staff, who have specialized knowledge in seal production, will advise you on the optimal materials and processing methods.

We also offer Norigoroshi processing, and on the page below you can find a preliminary quote for attention seals. Please check it out.

Preliminary Quote for Attention Seals

For an exact amount, please feel free to contact us via the Quotation Page.

Case Studies of Attention Seals Using Norigoroshi

Finally, here are some attention seals produced by our company. Attention seals are effective in appealing to end users.

We can produce a wide variety of attention seals so that you can choose from among many options. For example, we can produce seals with adhesive applied only on the front, seals with deformed Norigoroshi processing, and even printing on the non-adhesive areas, catering to a wide range of applications.

If you have any concerns regarding product attention seals, eye-catching seals, or POP seals, please feel free to contact us.

For more details on attention seals, please refer to the article below.

Consult with a Printing Company to Produce Your Ideal Norigoroshi Processed Seals

Norigoroshi processing is a method that eliminates the adhesiveness of a portion of seals and labels. It is mainly used for attention seals to effectively promote products and to make seals easier to peel off.

At our company, we produce various seals and labels tailored to your specific usage as illustrated in the article above.

If you are considering label or seal production, we will carefully support you from choosing the adhesive and material to the final product. Please feel free to contact us.

Start Your Project Now!

Contact Us or Get a Quote!