Label Printing Finish Selection: Choose from 5 Types

When creating labels, convenience should be considered.Stickers may be applied automatically or manually, one by one, to products. This page explains five different delivery forms. We hope this will be helpful when ordering stickers and labels.

Please feel free to contact us.

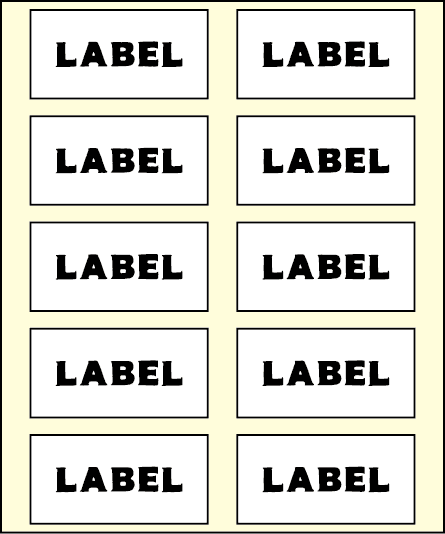

Sheet Cut Finish

Sheet cut stickers are convenient for manual application. Multiple stickers are attached to one sheet. For example, a sheet can have 2 columns by 5 rows, depending on the sticker dimensions. We ensure ease of use by limiting the maximum sheet size to 300×300mm. Sheet cuts are also cost-effective since they do not include the cost of finishing each sticker individually. Small batches of 1000 to 3000 pieces are typically produced in a single column.

Single Cut Finish

As the name suggests, single cut stickers feature one sticker per sheet. They are often used for distribution purposes rather than application. Although the backing paper is larger than the sticker, making it appear less attractive, it has advantages. The larger backing paper makes the sticker easier to peel off, and it protects the sticker from side damage. Single cut stickers are more expensive than sheet cut stickers due to the additional cutting cost.

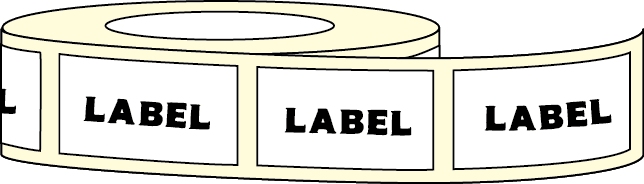

Roll Finish

This format is suitable for machine application using an automatic labeller. For attaching over 5000 stickers or labels, automatic labelling is recommended (although it can also be used for manual application, with demand comparable to sheet cuts). Rolls can be wound in an outward or inward direction. You can choose the dispensing direction: right, left, top, or bottom. *Please specify the direction at the time of order as it varies depending on the labelling machine.

If you are looking for cost-effectiveness, we recommend "optimal roll finish." By maximizing the number of labels per roll, processing costs are reduced. Conversely, fewer stickers per roll will increase processing costs. We recommend at least 1000 stickers per roll.

Cut Finish

This option is often chosen when distributing individual stickers. Cutting involves slicing the sides of a stack of stickers at once, resulting in stickers and backing paper of the same size. This provides a better appearance compared to sheet cuts where the backing paper is larger. Adding slits (back cuts) to the backing paper makes it easier to peel off the sticker by slightly bending the paper.

Punch Cut Finish (Die Cut)

This method is suitable for irregularly shaped stickers. Using a die, the sticker and backing paper are cut together, resulting in stickers with the same dimensions as the backing paper, providing a clean appearance. Adding slits (back cuts) to the backing paper also makes it easier to peel off the sticker. The more complex the shape, the higher the cost of the die.

Summary of Sticker Finishes

Deciding on the finish before ordering stickers will facilitate smoother communication with the printing company. Here is a quick summary for reference:

Sheet Cut ... Product Labels

Single Cut ... Stickers

Roll ... Product Labels

Cut ... Stickers

Punch Cut ... Stickers

Related Articles

Easy Guide to Tack Paper

Comprehensive Guide to Adhesives for Different Applications

Start Your Project Now!

Contact Us or Get a Quote!