What is Perforation Processing? Features, Processing Methods, and Case Studies

Perforation processing is a technique that creates wavy cuts in paper, making it easy to tear off. In this article, we introduce the features, types, and precautions of perforation processing. If you are considering producing products using perforation processing, please use this as a reference.

Our company is a printing firm specializing in labels and seals, offering various types of seals. If you have any concerns or questions regarding label or seal production, please feel free to contact us using the link below.

For those struggling with label and sticker printing

Wondering if this kind of printing is possible? Or how much budget is needed?

If you have any concerns, feel free to reach out to us.

First, check out our case studies.

※Orders are available starting from 1,000 pieces.

※Business hours: Japan Standard Time, Monday to Friday, 9:00 AM - 5:00 PM

What is Perforation Processing?

Perforation processing is a method of creating fine, wavy cuts in paper to facilitate easy tearing.

Its main functions are primarily the following two:

- Tear-off line

- Crease line

The tear-off line is designed so that the paper can be torn off along the perforation. It is widely used in items such as tickets and coupons, allowing smooth separation without scissors.

On the other hand, the crease line is applied to materials that are difficult to fold, such as thick paper or tracing paper, by creating perforations that make them easier to bend. By using perforations instead of traditional creases, the material can be easily folded.

Standard Perforation Processing Method

The standard method of perforation processing involves applying perforations in a straight line from one edge of the paper to the other. This method is commonly used for tickets, coupons, and easy separation of labels, serving as a tear-off line that allows for easy manual separation.

There are several methods to create standard perforations, but typically a slit perforation machine is used. This machine presses a rotary cylinder with a circular perforation blade against the paper, feeding one sheet at a time between the cylinder and the blade to continuously create uniform perforations.

Using a slit perforation machine results in uniform and attractive perforations, making it easy to tear the paper smoothly.

Specialized Perforation Processing Methods

In addition to standard perforations, there are specialized processing methods available. The following two techniques allow for even more precise processing to meet specific needs:

- Micro Perforation

- Lead Ruling

Special Technique 1: Micro Perforation

Micro perforation is an even finer perforation process than standard perforation. It not only makes tearing off easier but also results in perforations that are less noticeable, yielding a clean, crisp tear when separated.

The cut width is set to 0.35mm with an interval of 0.15mm, producing a very fine and smooth cut without a jagged edge.

This method is ideal for high-end tickets or product labels where both appearance and functionality are important, and where a more refined finish is desired.

Special Technique 2: Lead Ruling

Lead ruling is a specialized technique that alternates short cut lines with crease lines to make paper easier to fold. It is mainly used on packaging, such as cosmetic boxes that can be assembled with a single touch, where perforations on the sides or back facilitate smooth assembly.

While standard perforation processing is used to create continuous tear-off lines, lead ruling is intended to assist with folding. It is particularly suitable for thick paper or packaging that is frequently opened and closed.

Precautions for Perforation Processing

The main precautions to consider when performing perforation processing are the following two points:

- Adjust the length of the cuts and the spacing

- Some perforation processes may be challenging to execute

Precaution 1: Adjust the Length and Spacing of the Cuts

The ease of tearing or folding the paper is influenced by the "pitch," which refers to the length of the cuts and the spacing between them.

By choosing the optimal pitch for your intended purpose, you can achieve an ideal finish. Generally, a pitch of "2mm cut × 1mm space" is commonly used, but it is important to adjust the pitch according to the thickness of the paper and the intended application.

For example, thinner paper may benefit from a shorter pitch, such as "1.5mm cut × 0.5mm space," to avoid difficulty tearing.

Conversely, for thicker paper, a longer pitch can be more effective. By making slightly longer cuts, even rigid paper can be torn off easily.

Our company offers three standard types of perforation processing:

- 1mm cut, 1mm space

- 2mm cut, 1mm space

- 3mm cut, 1mm space (the easiest to tear)

Other dimensions can be accommodated with custom orders, but this may increase the cost. Generally, either these three types or the use of micro perforation is common.

Precaution 2: Some Perforation Processes Are Difficult to Execute

There are various types of perforation processing, but because they require specialized techniques and equipment, not all printing companies may be able to accommodate them.

The following are examples of perforation processes that are considered particularly challenging:

- Perforating at an angle to the edge of the paper

- Curved perforation processing

- Combined processing with crease lines

- Perforation processing with extremely narrow spacing

If you wish to request such processing, it is important to consult with the printing company in advance to confirm whether it is feasible.

Label Materials That Work Well with Perforation Processing

Perforation processing is compatible with a wide range of materials. For example, because the pitch of perforations is very fine, it works well with high-quality paper that has minimal unevenness, such as premium paper.

It is also used on "virgin seals" for cosmetic and pharmaceutical packaging. Virgin seals are designed to guarantee that the product remains unopened, with perforations that tear cleanly upon opening.

They are made from transparent film materials (such as Transparent PET) and protect the opening or lid, thereby enhancing consumer confidence and increasing product value.

Our company handles a wide variety of materials suitable for perforation processing and can propose the optimal label material based on the application and usage environment. If you have any concerns about material selection or processing, please feel free to contact us.

Case Studies of Product Labels Using Perforation Processing

Seal Sticker

This is a seal sticker with perforations. It indicates that a product has not been opened and helps prevent tampering. It is often used on food and cosmetic products. The perforations make it easy to tear off.

Multilingual Label

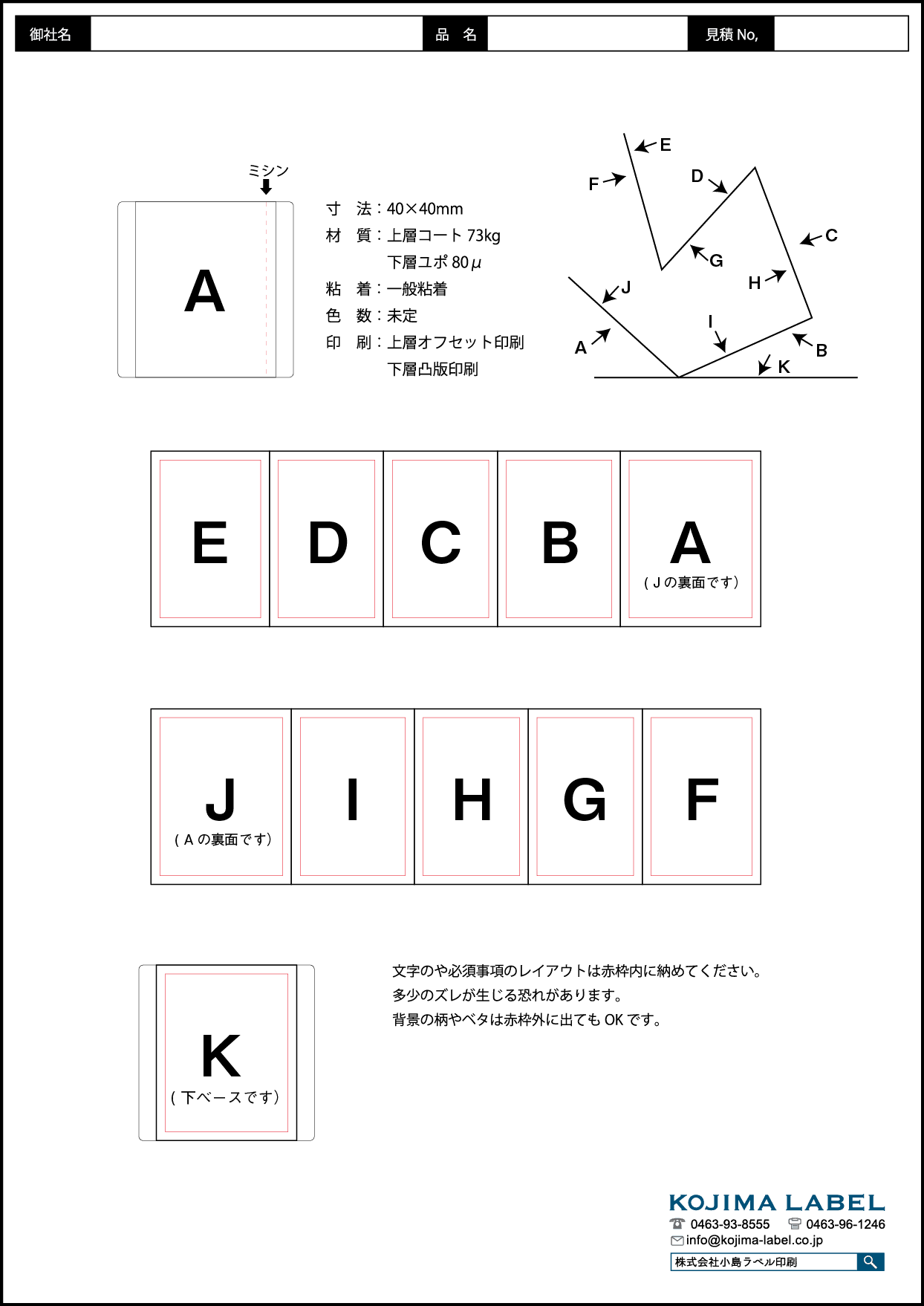

Finally, here is a case study of a "multilingual label" produced using perforation processing.

Multilingual labels display the same information in multiple languages and are also known as multi-layer labels or leaflet seals. They are ideal when it is necessary to include warnings or instructions in Japanese, English, Chinese, French, and other languages on products or shipping packages.

The label is designed to be folded page by page, and it opens sequentially along the perforation so that the necessary information can be easily reviewed.

This label supports submission in Illustrator data format, and we provide format data adjusted to the finished size and the number of pages as shown below.

The format data allows you to decide on the design layout smoothly. For more details on multi-layer labels, please refer to the article below.

Multilingual Label (Multi-layer Label) | A Convenient Label for Overseas Exports

Recipe Seal | We Created a Mini Recipe Book with Seals!

Create the Ideal Label Seal with Perforation Processing

Perforation processing is a method used to make paper or seals easy to tear off by hand, or to make them easier to fold. However, because some complex perforation processes can be challenging, it is recommended to confirm with the printing company in advance whether they can accommodate your requirements.

Our company produces various product labels and seals tailored to different applications, including the multi-layer labels mentioned in this article. If you are considering label or seal production, we will support you carefully through to completion, so please feel free to contact us.

Start Your Project Now!

Contact Us or Get a Quote!