Label Enhancement Guide with Examples and Tips

Enhance your seals with lamination, foil stamping, and more.

Seal enhancements—also known as label enhancements—add shine, texture, and durability beyond standard printing. This guide covers key benefits, common types, and tips for choosing the right finish.

We offer custom label printing with expert support to match your vision. Contact us to explore the possibilities.

For those struggling with label and sticker printing

Wondering if this kind of printing is possible? Or how much budget is needed?

If you have any concerns, feel free to reach out to us.

First, check out our case studies.

※Orders are available starting from 1,000 pieces.

※Business hours: Japan Standard Time, Monday to Friday, 9:00 AM - 5:00 PM

What Is Seal Enhancement? (Also Known as Label Enhancement)

In label printing, seal enhancement refers to adding finishing processes—such as lamination or foil stamping—to improve the look, feel, and performance of a printed label. These enhancements are commonly used on product packaging and promotional materials to add value beyond standard printing.

There are various types of seal (or label) enhancements, each offering distinct benefits. Below are three key advantages of using these techniques:

Benefit 1: Improved Functionality

One major benefit of seal enhancement is enhanced functionality. Finishes like lamination help protect the printed surface from moisture, abrasion, and wear, increasing water resistance and durability. Some enhancements also make the label easier to peel or apply.

By adding new features through enhancement, labels can serve more practical purposes than before. This expands their range of use and increases overall product value.

Benefit 2: Added Luxury and Uniqueness

Seal enhancements can create a premium or exclusive feel that standard printing cannot achieve. For example, foil stamping and lamination add a glossy finish, while embossing or domed resin (potting) techniques bring dimensionality and texture.

These visual and tactile upgrades help your labels stand out and leave a lasting impression.

Benefit 3: Enhanced Design Possibilities

Seal enhancement broadens the design potential of your labels by adding shine, depth, and texture. These effects allow for more creative, original designs that can’t be achieved with ink alone.

This makes enhanced labels ideal for industries that prioritize visual impact—such as fashion, cosmetics, or art-related products.

Types of Seal Enhancements (Label Finishing Options)

Here are some of the most common types of seal enhancements used in label printing.

- Lamination

- Foil Stamping

- Embossing

- Silk Screen Printing

- Domed Resin Coating

- Adhesive Deactivation

Type 1: Lamination

Lamination is a process in which a clear film—typically made of polypropylene (PP)—is applied to the surface of a label to protect it and add either a glossy or matte finish. There are two main types of lamination: gloss lamination and matte lamination.

Gloss lamination uses a shiny film that enhances the vibrancy of printed colors and gives the label a polished, eye-catching appearance. It is ideal for labels that require a bright and luxurious look.

Matte lamination, on the other hand, uses a non-reflective film that creates a calm, sophisticated finish by reducing glare. It also improves readability, making it a great choice for labels with text or fine details.

For more details on lamination, please refer to the link below.

Types and Features of Lamination Processing: Water Resistance and Effects on Stickers

Type 2: Foil Stamping

Foil stamping is a finishing technique where metallic or holographic foils—such as gold, silver, or rainbow foil—are pressed onto the label surface to create a luxurious and premium feel.

When used for brand logos or product packaging, foil stamping adds strong visual impact and helps differentiate your product from competitors. It is also a versatile process that works on various materials and does not require specific thickness conditions, offering greater design flexibility.

For more information on foil stamping, please refer to the following articles:

What is Foil Stamping? Features and Key Considerations

Hologram Foil Stamping: Features and Benefits

Type 3: Embossing

Embossing is a finishing technique that creates raised or recessed patterns on paper by applying pressure, allowing specific text or designs to stand out without using ink or foil.

Because it relies solely on texture rather than color, embossing produces a subtle yet elegant and high-end appearance. Paper materials are better suited for this process than films, and it is generally not recommended for very fine or intricate designs.

For more details on embossing, please refer to the link below.

Embossed Labels Explained | Elevate Your Impressions!

Type 4: Silk Screen Printing

Silk screen printing is a method that allows ink to be applied in thick layers, making designs more pronounced and suitable for use on curved or three-dimensional surfaces.

Because the ink adheres well and resists peeling, this technique is often used for outdoor signs and durable stickers. While it is not ideal for full-color or high-resolution images, it works well on a wide variety of materials, making it a versatile option for many applications.

For more details on silk screen printing, please refer to the link below.

What Is Silk Screen Printing? Differences from Offset printing

Type 5: Domed Resin Coating

Domed resin coating, also known as doming or resin-sealed labels, is a finishing process where a layer of clear resin is applied to the surface of a label to create a raised, dome-like appearance.

This coating not only enhances visual appeal with its glossy, dimensional effect, but also improves water resistance and durability—making it suitable for outdoor use. Although more expensive than other enhancement methods, it is widely used across industries for logos, emblems, and product nameplates due to its premium look and lasting quality.

Because of the nature of the resin, this process is best suited for simple shapes such as circles, ovals, or rectangles.

For more details on domed resin labels, please refer to the link below.

Domed Stickers Explained | The Coating Process

Type 6: Adhesive Deactivation

Adhesive deactivation, also known as selective adhesive removal, is a process that reduces or eliminates stickiness on specific areas of a label using varnish or film. The treated sections become non-adhesive.

This technique is often used for attention-grabbing POP labels with protruding elements that enhance product visibility on shelves. It also makes labels easier to peel, making it practical for user-friendly packaging or interactive designs.

For more details on adhesive deactivation, please refer to the link below.

What is "Nori-Goroshi"? Features, Processing Methods, and Recommended Materials

Collaboration with Your Printer Is Key: Things to Consider When Producing Enhanced Labels

When creating enhanced labels, keep the following three points in mind.

- Allow sufficient time for production

- Order in larger quantities to reduce unit cost

- Choose appropriate designs and materials for the enhancement type

Tip 1: Allow Sufficient Time for Production

When using seal enhancements, the production process involves additional steps compared to standard printing, which often results in longer lead times. It’s important to plan your schedule accordingly by working backward from your desired delivery date.

To avoid delays, consider consulting with your printing company during the early planning stage. This helps ensure a smooth workflow and realistic timeline.

Tip 2: Order in Larger Quantities to Reduce Unit Cost

Enhanced labels typically cost more than standard label printing, especially when ordered in small quantities. To keep unit prices lower, it's recommended to place larger batch orders whenever possible.

Tip 3: Choose Designs and Materials That Match the Enhancement

Some enhancement methods may limit the types of materials or paper that can be used. For example, certain finishes work only with specific substrates or surface conditions.

If you already have a preferred enhancement in mind, it’s a good idea to check with your printing company in advance to understand any material or design constraints.

At Kojima Label Printing, we're happy to assist you in selecting suitable materials and finishes. Feel free to contact us if you're considering label production or enhancements.

Case Studies: Enhanced Label Projects

Finally, here are four examples of enhanced labels we’ve produced at Kojima Label Printing.

- [Lamination] Explosion G.K. – Promotional Label

- [Foil Stamping] Yorocco Beer Co., Ltd. – Product Label

- [Embossing] Holy Live Inc. – Product Label

- [Domed Resin Coating] Hitsujisanrise – Promotional Label

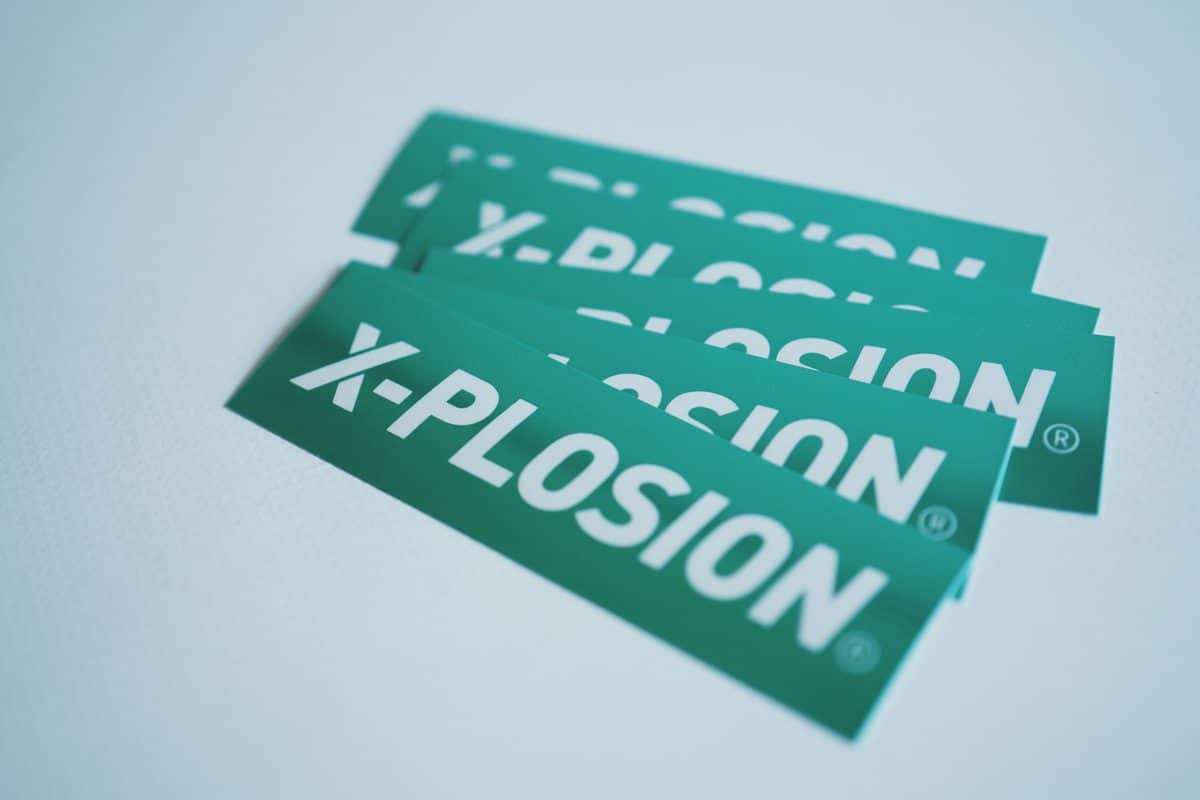

Case 1: [Lamination] Explosion G.K. – Promotional Label

We produced glossy laminated promotional labels for Explosion G.K., a company that sells protein and other health supplements and operates sports gyms.

The labels are printed on synthetic YUPO paper and protected with a gloss laminate finish, making them suitable for outdoor use. This finish also helps prevent wear and tear when applied to high-touch items like smartphones.

For more details about this case, please see the article below.

X-PLOSION LLC - Foil Stamping Stickers

Case 2: [Foil Stamping] Yorocco Beer Co., Ltd. – Product Label

The label for Washed Out by Yorocco Beer features a classic and refreshing design.

In addition to black and light blue ink, gold foil stamping was applied to accent key elements. The label is printed on YUPO 80μm synthetic paper with a strong water-soluble adhesive, providing excellent resistance to moisture and condensation when applied to cans.

For more details about this project, please see the article below.

Yorocco Beer Washed out label

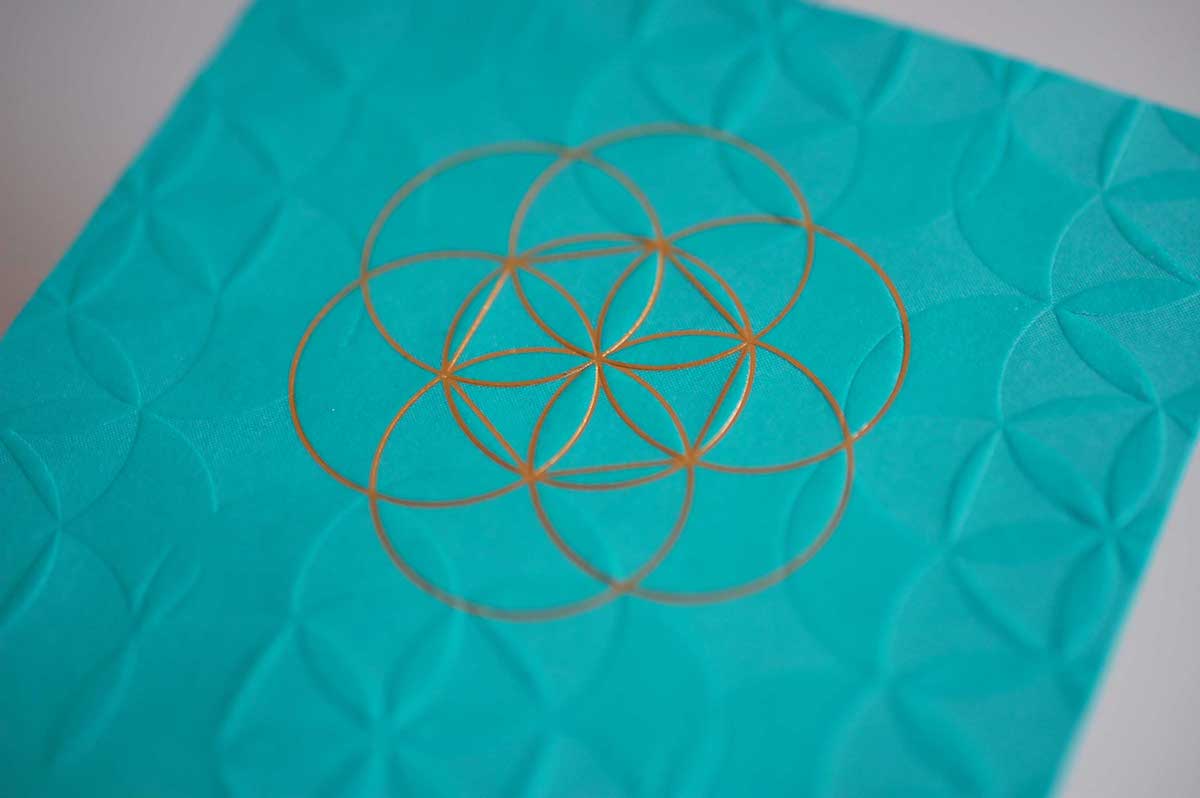

Case 3: [Embossing] Holy Live Inc. – Product Label

This is a label we produced for a pouch used to package supplements.

Embossing was used to create a textured pattern, while foil stamping highlighted the logo—resulting in a luxurious finish despite the limited color palette. The full-surface embossing adds a subtle, rhythmic sense of depth across the label.

For more details about this project, please see the article below.

Holy Lives Co., Ltd. - Embossed + Foil Stamping Stickers

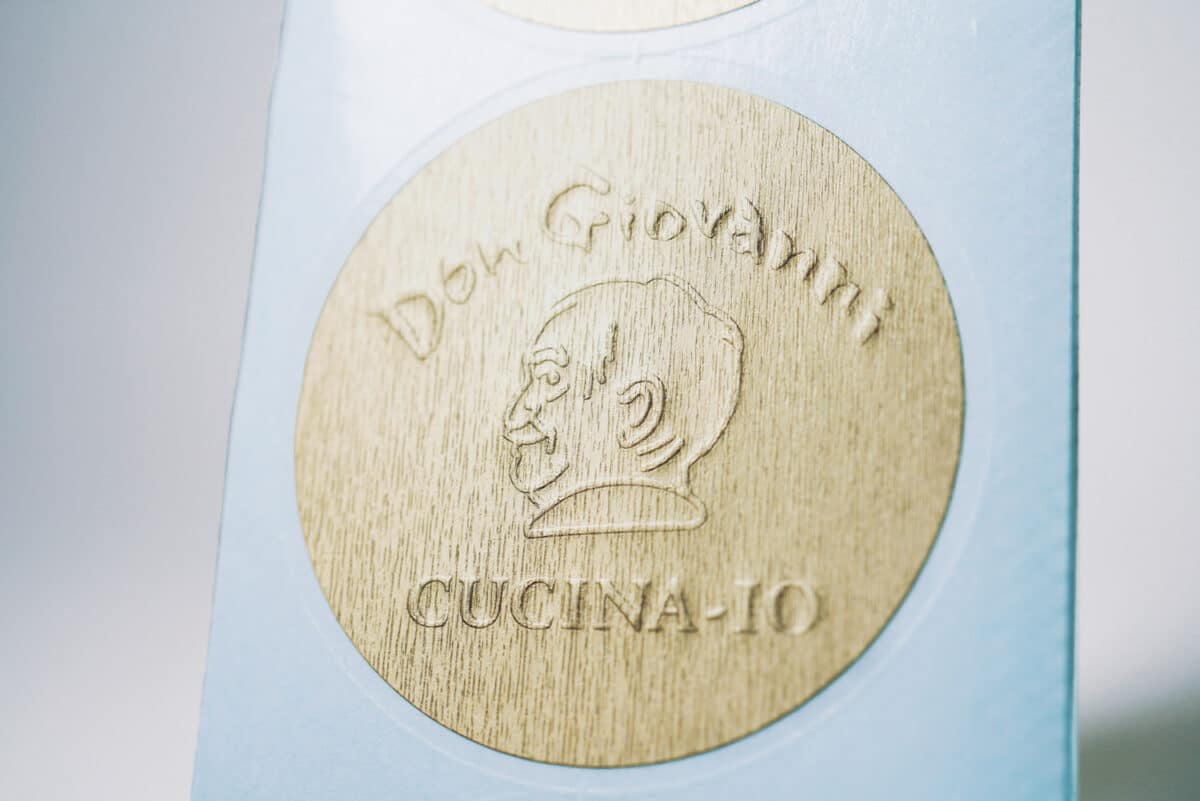

Case 4: [Domed Resin Coating] Hitsujisanrise – Promotional Label

This is a logo sticker we produced as a novelty item for a Genghis Khan (lamb BBQ) restaurant.

To increase the sticker’s perceived value, we applied domed resin coating. The label and backing paper were die-cut to the same shape, making it easy to distribute as a promotional giveaway.

For more details about this project, please see the article below.

Sheep Sunrise - Domed Stickers

Understand the Features of Seal Enhancements Before You Begin

Applying enhancements to labels can increase their impact, add new functionality, and elevate the overall value of the product.

Seal enhancements are widely used for a variety of applications, including product labels, promotional stickers, attention-grabbing POP labels, and novelty items. While these enhancements can greatly improve the quality and appeal of a label, they may also increase production time and cost, and not all designs or materials are suitable for every type of finish.

At Kojima Label Printing, we offer a wide range of custom enhancement options tailored to the intended use—just like the examples shown in this article.

If you're considering label or sticker production, feel free to contact us. We’re happy to support you from adhesive selection to final production.

Start Your Project Now!

Contact Us or Get a Quote!