Sticker Making Guide: How to Create, Materials, and Examples

Stickers are durable and weather-resistant, making them ideal for long-term use, especially for outdoor applications.

In this article, we’ll cover how to create stickers, types of materials, and important tips for the production process. If you're considering making your own stickers, this guide will be a helpful reference.

As a printing company specializing in labels and stickers, we create custom stickers tailored to the specific needs of your products. If you're planning to create your own original stickers, feel free to contact us below.

For those struggling with label and sticker printing

Wondering if this kind of printing is possible? Or how much budget is needed?

If you have any concerns, feel free to reach out to us.

First, check out our case studies.

※Orders are available starting from 1,000 pieces.

※Business hours: Japan Standard Time, Monday to Friday, 9:00 AM - 5:00 PM

What Is a Sticker?

A sticker refers to any printed material with an adhesive backing, similar to a seal.

The term originates from the English word "stick" or "sticker," meaning "to adhere," which is how the term "sticker" came about.

There is no clear distinction or definition between terms like "seal" and "label," and they are often used interchangeably. To clarify, we have summarized the differences by use case in the table below.

| Applications | Seal | Label | Stickers |

| Decorations & Gifts | ◎ | ○ | ○ |

| Display & Classification | ◎ | ◎ | ○ |

| Seald | ◎ | ○ | × |

| Outdoor Advertising | △ | × | ◎ |

| Car & bike decorations | ○ | × | ◎ |

| Signboard | × | × | ◎ |

| Product packaging | ◎ | ◎ | ○ |

| Food labeling | △ | ◎ | × |

| Address display | ◎ | ◎ | × |

| Privacy Policy | ◎ | ○ | × |

| Novelty | ○ | △ | ◎ |

If you're unsure about how to use them, be sure to refer to the table above.

ステッカーの作り方

There are mainly two methods for making stickers.

- Create it yourself

- Request it from a printing company

Method 1: Create It Yourself

First, let's look at how to make your own stickers. By using commercially available sticker paper, you can easily create your own stickers. This method is ideal for those who want to try making a small batch or use them for personal purposes.

However, making your own stickers has both advantages and disadvantages. Please check the points below.

| Merit | Disadvantages |

| ・Easy to create ・Cost-effective ・Can be made in small quantities | ・Lower quality ・Time-consuming for large quantities |

Method 2: Request from a Printing Company

This method involves requesting stickers or labels from a printing company that specializes in them. By working with a printing company, you can create stickers with special processing, allowing you to differentiate yourself from other companies.

Below, we’ve summarized the merits and demerits of requesting from a printing company.

| Merit | Disadvantages |

| ・Higher quality than DIY ・Large quantities can be produced ・Special processing options available ・No hassle in production | ・More expensive than DIY ・Takes longer to produce |

When creating stickers for businesses or products, we recommend requesting a printing company.

For those considering the creation of novelty stickers, we’ve outlined the production methods and tips to enhance their effectiveness below.

How to Create Novelty Stickers: Methods and Marketing Tips

Sticker Production Process

Next, we’ll introduce the main production steps for creating stickers, divided into DIY and printing company options.

DIY Method

Stickers can be created using a home printer.

Below is a list of the items you'll need when creating them yourself.

- Computer

- Design editing software (e.g., Illustrator, Photoshop, Canva, etc.)

- Home printer

- Sticker paper

- Scissors, cutter

The steps for creating your own stickers are mainly as follows:

- Use a computer and design editing software to create the design for the sticker.

- Print the completed design onto sticker paper using a home printer.

- Use scissors or a cutter to trim the sticker to match the design.

Home printers often do not use water-resistant ink, which may cause the printed surface to smudge.

Requesting from a Printing Company

When you request from a printing company, they can create stickers tailored to your design, material, and intended use.

The main steps for creating stickers at a printing company are as follows:

- Communicate the desired quantity and specifications, and request a quote.

- Prepare the design data in-house (some printing companies may also offer design services).

- Submit the design data and place the official order.

- If necessary, request a paid prototype to check the design, texture, and color.

- Receive the completed stickers.

When creating product stickers, you can achieve higher quality than DIY. Additionally, since special processing options are available, we recommend requesting a printing company for product stickers.

On this site, we also provide detailed explanations on "How to Make Labels" and "How to Make Seals" in the articles below. If you're interested in sticker production or other topics, be sure to check them out.

How to Make Stickers : DIY Methods and Ordering Guide

Types of Paper for Sticker Bases

Sticker paper can be broadly categorized into two types: "paper-based" and "film-based" materials. Paper-based materials are vulnerable to water and can easily get dirty, making them suitable for indoor stickers.

On the other hand, film-based materials, made from processed plastics, are water-resistant and durable, making them ideal for outdoor stickers.

Below, we’ll introduce four types of film-based paper that are particularly recommended for sticker making.

- Yupo

- PVC

- Transparent PET

- Hologram

We also introduce the features and textures of these materials, so please use this as a reference when choosing the right material.

Material 1: Yupo

Made from polypropylene resin, Yupo is a synthetic paper known for its excellent durability and water resistance, making it ideal for outdoor and wet environments.

It is resistant to condensation and doesn’t wrinkle easily even with temperature changes such as those in refrigeration or freezing environments. The texture is similar to paper, with a smooth and silky feel. Additionally, Yupo is known for being cost-effective, offering excellent value for money.

For more detailed information about Yupo, please check out the article below.

Yupo is an inexpensive yet highly durable film material.

Material 2: PVC

PVC is a durable and water-resistant material, making it the ideal paper for outdoor stickers. It has a smooth texture, and is available in two types: gloss and matte.

There are three types: "White PVC," "Transparent PVC," and "Colored PVC."

| White PVC | ・A type that applies color printing to a white film. |

| Transparent PVC | ・Since it is printed directly in color, it results in a semi-transparent finish. ・It gives an effect similar to stained glass. |

| Colored PVC | ・Color film materials in black, red, blue, yellow, green, etc. ・Mainly used for industrial warning signs and display stickers. |

PVC is mainly used for stickers on cars, snowboards, helmets, and similar items.

For more detailed information about PVC, please check out the article below.

PVC is highly durable and suitable for outdoor use.

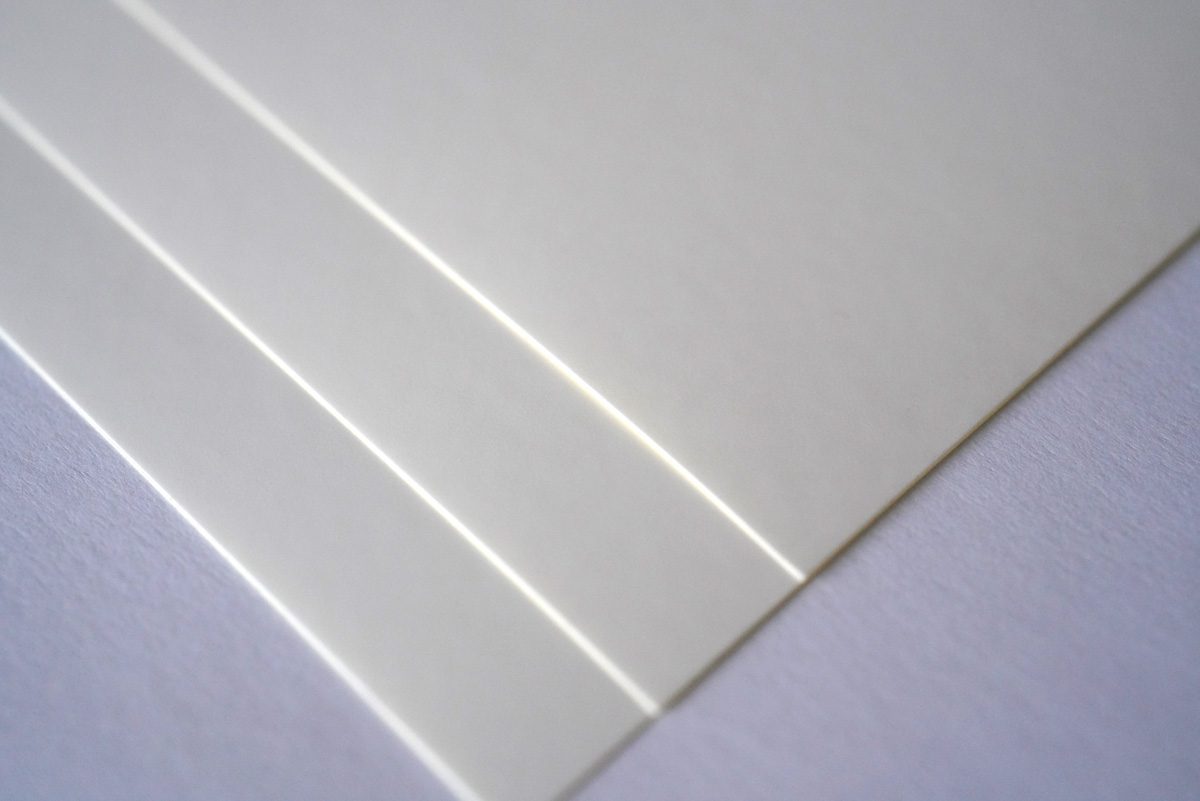

Material 3: Transparent PET

Transparent PET is a highly durable paper made from polyester film. Being transparent, it allows for a clean design by keeping everything except the printed areas subtle and unobtrusive.

Transparent PET is commonly used for creating clear stickers. It comes in two types: gloss and matte. The gloss type has a smooth texture, while the matte type has a silky, smooth feel. The main applications include window stickers and designs that utilize its transparency.

For more detailed information about transparent PET, please check out the article below.

Transparent PET is a highly durable film material. (The yellow appearance is the backing paper's color.)

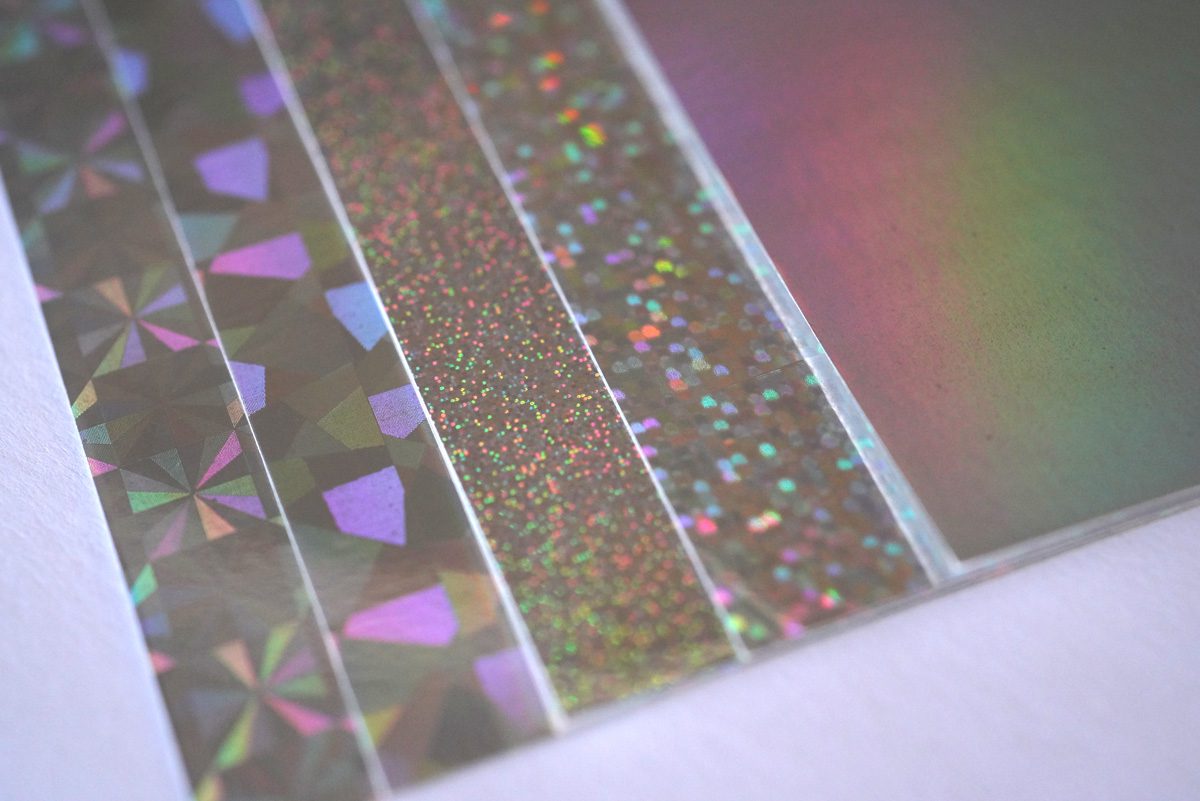

Material 4: Hologram

Hologram is a material that changes color based on the angle of reflection, making it highly eye-catching. The surface has a smooth, glossy texture.

When used outdoors, it lasts longer with a gloss laminate finish. Among film materials, hologram is on the higher end of the price spectrum and is mainly used for novelty stickers, decorative product labels, and limited-edition stickers.

For more detailed information about hologram materials, please check out the article below.

Creating Hologram Stickers: Patterns, Materials, and Prep

Types of Sticker Adhesives

There are different types of adhesives for stickers, and choosing the right one based on the intended use is key.

Below, we’ve summarized the types of adhesives and their features. Understanding these characteristics will help guide your adhesive selection.

| Types of glue | Features |

| Strong adhesion | ・Has strong adhesive power and is used when a firm attachment is required ・Suitable for situations where permanent or long-term adhesion is needed ・Mainly used for outdoor applications |

| General Adhesive | ・Has moderate adhesive strength and is used for indoor or temporary applications |

| Weak adhesion | ・Has weak adhesive strength and can be easily removed |

| Removal | ・Can be easily removed after application, leaving almost no residue ・Ideal for stickers that are meant to be applied for a limited time |

As a printing company specializing in seals and labels, we create a variety of stickers and seals. We also offer recommendations for the best paper and adhesive options tailored to your needs, so feel free to contact us through the "Inquiry" section.

Product Sticker Case Studies

Here, we showcase examples of stickers we have created in-house. Use these as a reference for your own sticker production.

- W&Rs Co., Ltd. - Hologram Stickers

- Explosion LLC - Foil Stamped Stickers

- ATC Store Co., Ltd. - Novelty Stickers Made with Biomass Materials

W&Rs Co., Ltd. - Hologram Stickers

We created hologram stickers for event announcements for W&Rs Co., Ltd. By using a red logo and frame, the hologram’s impact is kept subtle in the design.

The material used is "Hologram No.1," and the adhesive is strong. The production process involved printing white first, followed by red on top. The background was not printed in white, allowing the red-toned hologram to be the main focus of the sticker.

For more detailed information about the hologram sticker production case for W&Rs Co., Ltd., please check out the article below.

W&Rs Co., Ltd. - Hologram Stickers

Explosion LLC - Foil Stamped Stickers

Next, we’ll introduce the novelty stickers created for Explosion LLC.

The background is primarily black, and the logo features two types of matte gold foil stamping. The material used is Yupo, and the stickers are laminated for protection, making them suitable for outdoor use. The adhesive used is a strong adhesive, ensuring the stickers are firmly attached.

For more detailed information about the novelty sticker production case for Explosion LLC, please check out the article below.

foil-stamping-laX-PLOSION LLC - Foil Stamping Stickers

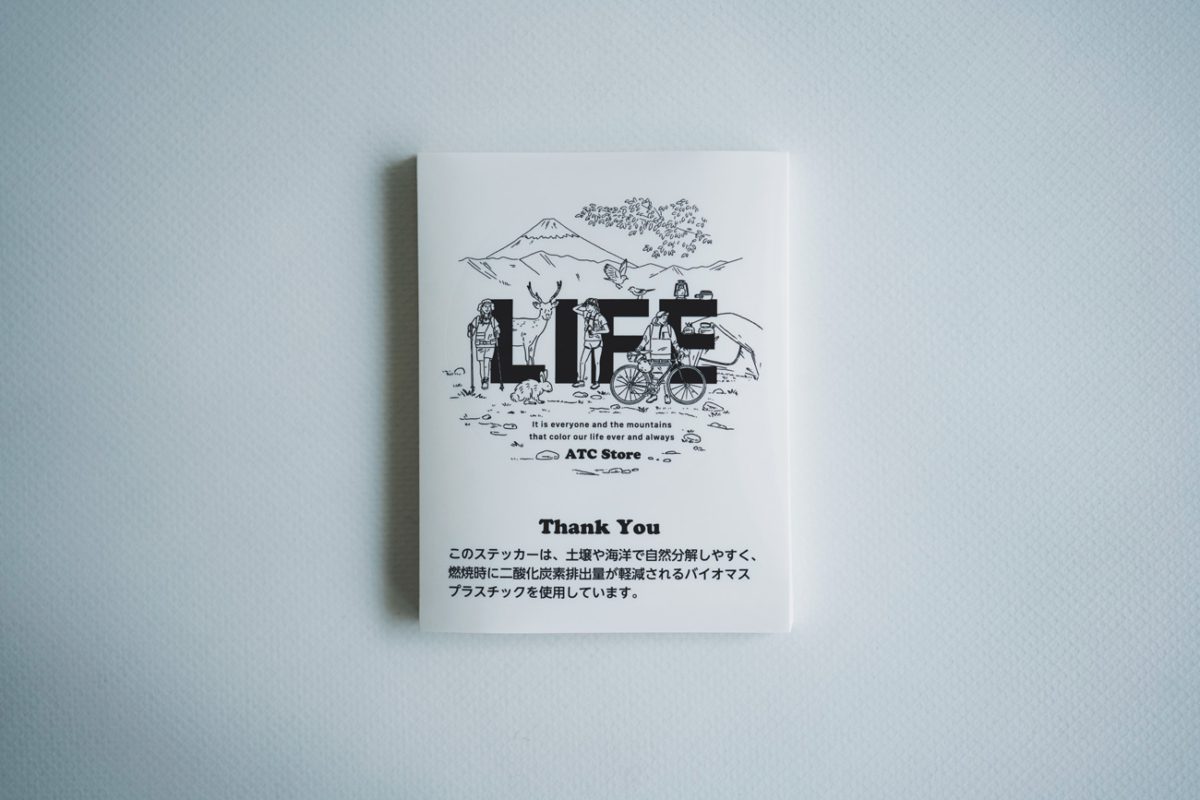

ATC Store Co., Ltd. - Novelty Stickers Made with Biomass Materials

This is a production case of novelty stickers for ATC Store Co., Ltd.

The material used is Eco Marine Tac, a bio-plastic that naturally decomposes in the adhesive area. It is an environmentally friendly material registered under the Ministry of the Environment's "Plastic Smart" campaign, which addresses the issue of "marine plastic waste." This material is particularly suitable for companies related to the environment or campaigns with a strong eco-conscious focus. However, it should be noted that it may shrink by about 2% due to humidity, so careful handling is necessary.

We also introduce more environmentally friendly materials in the article below.

Eco-friendly Materials

For more detailed information about the novelty sticker production case for ATC Store Co., Ltd., please check out the article below.

ATC Store Co., Ltd. - Biomass Promotional Stickers

Things to Keep in Mind When Making Stickers

Finally, let’s go over some important points to keep in mind when making stickers.

The main points to consider are the following three:

- Choose the material that suits the intended use

- Select the appropriate adhesive based on the purpose

- Die-cut stickers may be difficult for intricate designs

注意点1 用途に適した用紙選びをする

ステッカーを制作する際は、使用する環境や目的に合った素材選びが大切です。適切でない素材を選ばないと、ステッカーの寿命が短くなったり、見た目が損なわれたりする可能性があります。

例えば、紙素材はコストが比較的安い点が魅力ですが、耐水性に劣るため、屋外や湿気の多い場所での使用は適しません。

また、ラミネート加工を施さず印刷したステッカーは、雨や日光、湿気にさらされると文字やデザインが消えてしまう場合もあります。使用環境や目的に合った素材を選ぶことで、ステッカーの品質を維持し、長期間にわたり効果的に使用することが可能です。

Point 1: Choose the Right Material for the Intended Use

When making stickers, it is important to choose a material that suits the environment and purpose of use. Selecting the wrong material can shorten the lifespan of the sticker or affect its appearance.

For example, paper materials are relatively inexpensive, but they lack water resistance, making them unsuitable for outdoor use or humid environments.

Additionally, stickers that are printed without lamination may lose their design or text when exposed to rain, sunlight, or moisture. By selecting the right material for the environment and purpose, you can maintain the quality of the sticker and ensure its effective use for a long time.

Point 2: Choose the Right Adhesive Based on the Purpose

When choosing an adhesive, it’s important to select one that matches the intended purpose. Different adhesives have varying effects, so it’s crucial to choose the right one for your needs.

For example, if you want to remove a sticker cleanly after it’s applied, a low-adhesive type that leaves no residue is recommended. On the other hand, if you want a sticker to stay securely in place for a long time, a strong adhesive that resists peeling is the best choice.

However, adhesives may not perform as effectively depending on the surface or material they are applied to. Therefore, it’s important to choose the optimal adhesive based on the purpose and environment.

For more detailed information on adhesives and their features, please check out the article below.

Adhesive Labels

Point 3: Die-Cut Stickers May Be Challenging for Intricate Designs

Die-cut stickers, unlike regular square stickers, are cut into custom shapes from the backing paper. This feature allows for unique and original designs, but intricate designs may not always be suitable for die-cutting.

In particular, characters with many strokes, such as complex kanji, or very small text, may not be possible to reproduce, so caution is required.

If you’re aiming for a detailed design, it’s recommended to consult with a printing company. They can provide advice on adjusting line thickness for die-cutting, fine-tuning the design's level of detail, and selecting the right material based on your needs.

Create Stickers That Suit Your Company

There are two ways to create stickers: "DIY" and "Request from a printing company." DIY allows for low-cost production but requires more effort and has limitations in quality. On the other hand, requesting from a printing company incurs more cost, but allows for high-quality sticker production.

For company or product stickers, it is recommended to request from a printing company, where you can consult not only about quality but also about material and adhesive selection.

As a printing company specializing in seals and labels, we create stickers like those introduced in the article. We provide careful support from material selection to product completion, so feel free to contact us.

Start Your Project Now!

Contact Us or Get a Quote!