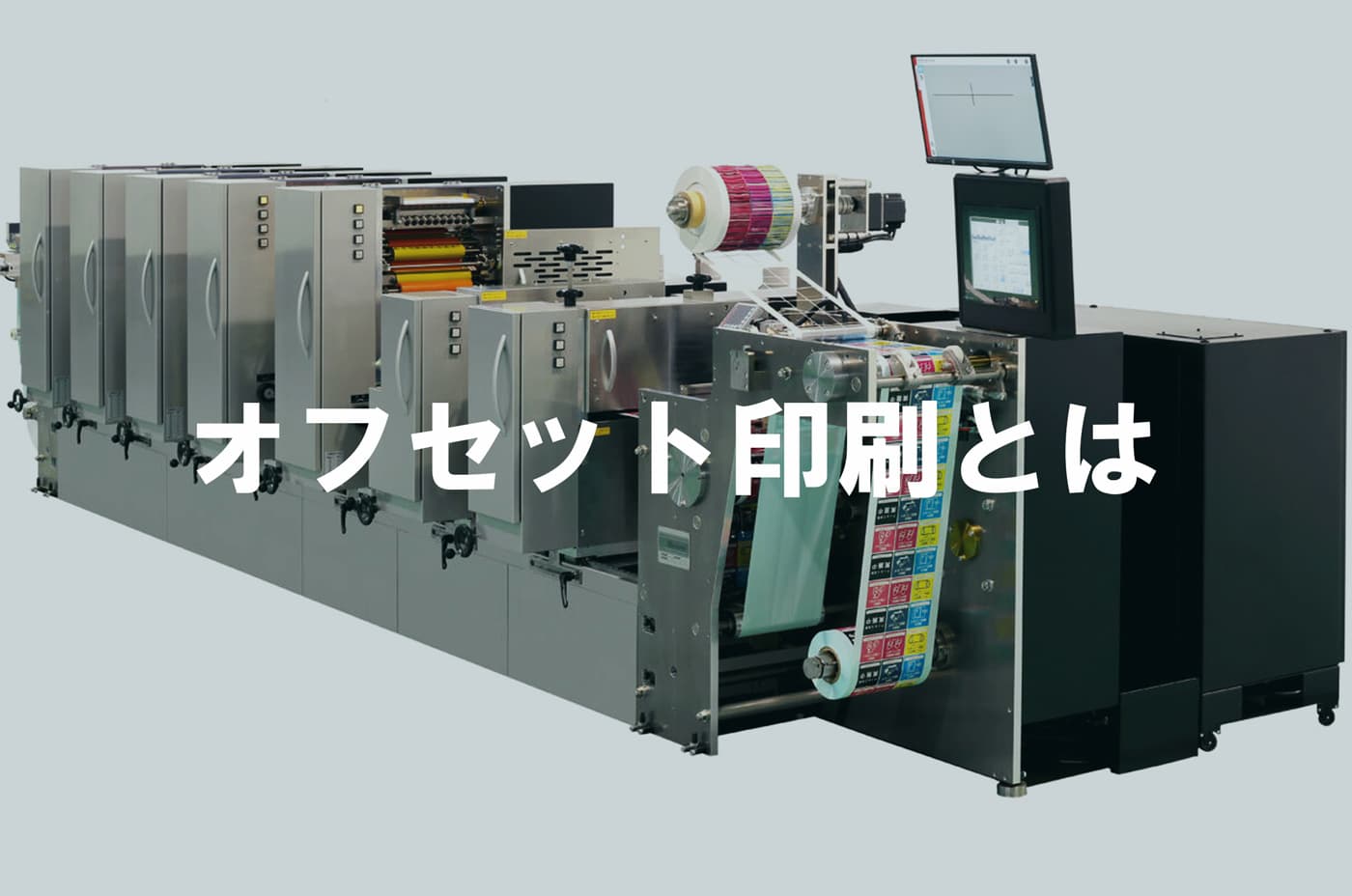

What Is Offset Printing? Process, Differences, and Uses

Offset printing is commonly used for books, magazines, flyers, and more. Known for its beautiful finish, it is not suitable for all types of materials.

This article covers the basics of offset printing, its differences from on-demand printing, and the types of materials best suited for it. For those interested in high-quality production or learning more, continue reading.

We also offer sticker production with offset printing. If you’re considering this method for your printed materials, feel free to contact us using the links below.

Please feel free to contact us.

What is Offset Printing?

Offset printing is widely used for books, magazines, flyers, posters, and more. By using "plates," this technique can achieve clear and detailed results, especially for large print runs.

It is a widely adopted and popular method among many companies today. In this process, ink (oil) is applied to a flat aluminum "plate."

The ink is then transferred (OFF) to a rubber roller called a blanket, and finally applied (SET) from the blanket onto the paper. This transfer process is why it’s called "offset." Additionally, it is sometimes referred to as "planographic printing" due to its use of flat plates.

Differences Between Offset Printing and On-Demand Printing

When researching print methods, you might encounter "on-demand printing." Here, we’ll outline how it differs from traditional offset methods.

Key differences include the use of "plates," the type of ink, and the quality of the final output. On-demand processes skip the plate stage and can start immediately after data submission, similar to how home or office multifunction devices operate.

Below is a summary of the main distinctions between traditional and on-demand methods:

| Offset Printing | On-Demand Printing | |

| Plates | Required | Not required |

| Type of Ink | Ink | Toner/Inkjet |

| Suitable Lot Size | At least 1,000 copies | Less than 1,000 copies (small lots) |

| Cost per Unit | High for small lots | High for large lots |

| Design Changes | Plate cost incurred | No plate cost |

| Resolution | Very high | Somewhat lower |

| Target Audience | Corporations | Shops and individuals |

Offset printing is suitable for high-quality, large-volume printing of 1,000 copies or more.

On the other hand, on-demand printing is suitable for small quantities or printing materials with frequently changing designs. When choosing a printing method, consider the content and budget of the printed materials you are requesting.

For more details about on-demand printing, please refer to the following article:

On-Demand Printing

How Offset Printing Works: Process and Structure

The key points related to the mechanism of offset printing are as follows:

- Offset Printing Process

- Offset Printing Structure

- Types of Offset Printing Machines

Understanding the mechanism of offset printing will be helpful when requesting printed materials.

Offset Printing Process

First, let's introduce the process of offset printing. The main steps are as follows:

Offset Printing Process

- Planning & Design: Outline the design of the printed material

- DTP Production: Create the print-ready artwork

- Plate Making: Create the printing plate and confirm color proofs

- Printing: Print based on the plate

- Finishing: Perform necessary finishing processes such as folding and trimming

- Delivery: Deliver the finished printed materials

The printing process may seem lengthy, but it can be divided into three main stages: "Prepress" (steps 1-3, before printing), "Press" (step 4, printing), and "Postpress" (steps 5-6, finishing and delivery).

Understanding these stages will help you better understand the progress of your printed materials.

Offset Printing Structure

As mentioned earlier, offset printing uses flat aluminum plates. It utilizes the repelling properties of water and ink (oil), separating the plate into areas that accept ink and those that do not.

The specific structure is as follows:

- The plate is mounted on the plate cylinder

- Ink and dampening solution are supplied to the plate

- The inked plate transfers the image to a rubber blanket

- The image is printed from the blanket onto the paper

This structure allows for detailed and high-quality printing.

Types of Offset Printing Machines

There are two types of offset printing machines: "sheet-fed presses" and "web presses." Each has different characteristics, and choosing the appropriate printing machine can help improve printing efficiency.

The characteristics of each type are summarized in the table below.

| Type of Printing Machine | Characteristics |

| Sheet-fed Press | ・Prints on cut sheets of paper ・Can print on paper of different sizes and thicknesses, making it flexible ・Suitable for flyers, booklets, etc. |

| Web Press | ・Prints continuously on roll paper ・More productive than sheet-fed presses ・Can quickly print large quantities, such as newspapers, magazines, and books |

It is important to choose the optimal printing machine based on the quantity to be printed, type of paper, and delivery deadlines.

3 Advantages of Offset Printing

The three main advantages of offset printing are as follows:

- Can print large quantities in a short time

- High-quality finish with accurate color matching

- Cost-effective for large print runs

Understanding these advantages can help you use offset printing more effectively.

Advantage 1: Can Print Large Quantities in a Short Time

Using a large offset printing machine, you can print large quantities quickly, such as books or large batches of flyers. It is also possible to print different printed materials, such as flyers and leaflets, at the same time on the same paper.

Especially with a web press, you can print continuously on roll paper, enabling even faster large-scale printing. While there is a pre-press process to create the plates, once the plates are made, additional prints can be produced quickly for future needs.

Advantage 2: High-Quality Finish with Accurate Color Matching

Offset printing uses highly adhesive oil-based inks, which allow for vibrant colors and sharp printing of images and text. There is little risk of smudging, resulting in high-quality, stable prints.

Because it can achieve precise color matching, it is recommended for printed materials that require high quality, such as art catalogs or company brochures.

Advantage 3: Cost-Effective for Large Print Runs

While there is a cost involved in creating the plates for offset printing, the cost per sheet can be reduced significantly with large print runs. The more you print, the lower the printing cost per unit.

However, for small print runs, the cost per sheet tends to be higher. As a general rule, printing more than 1,000 copies can help reduce costs.

This is just a guideline, as actual printing costs will vary depending on the size of the printed materials and the type of paper used. It is important to consult with the printing company in advance before placing an order.

3 Disadvantages of Offset Printing

The three main disadvantages of offset printing are as follows:

- Not suitable for variable printing

- Longer delivery times

- CO2 emissions

Knowing these disadvantages can help you make an informed decision when choosing the best printing method.

Disadvantage 1: Not Suitable for Variable Printing

While offset printing excels in high-quality, large-volume printing, it is not suitable for all situations. Because it uses plates, it is not ideal for variable printing (although this can be done in a separate process).

For example, printing different addresses and names on "New Year's cards" or flyers with individual campaign codes is not suitable for offset printing (this can be done with on-demand printing).

Disadvantage 2: Longer Delivery Times

When ordering for the first time or with a new design, time is needed to create the plates. Additionally, this method requires drying time after the ink is transferred to the paper. It is important to plan and allow enough time when placing your order.

If you have an urgent project or need a quick turnaround, consider the time required for this process and either look for alternative methods or choose a provider that can meet tight deadlines.

Disadvantage 3: CO2 Emissions

Offset printing produces CO2 emissions during the plate-making and printing processes.

According to a comparison study by the Japan Association of Graphic Arts Technology (JAGAT) on CO2 emissions from digital printing and offset sheet-fed printing, the plate-making process for offset printing accounts for 4 to 50% of the total CO2 emissions.

Additionally, it is explained that the increase in the actual number of sheets used due to the addition of ink to waste paper (spoiled paper, test prints) can pose an environmental burden. Reference: Comparison of CO2 Emissions from Digital Printing and Offset Sheet-Fed Printing|Japan Association of Graphic Arts Technology (JAGAT)

However, while the proportion of CO2 emissions from the plate-making process is high for small runs, this proportion decreases as the print run increases. Therefore, beyond a certain number of copies, the CO2 emissions from offset printing can be lower than those from digital printing.

Additionally, traditional UV (ultraviolet) curing systems used in offset printing, which consume high amounts of power, are increasingly being replaced by energy-efficient LED UV curing systems. The introduction of these LED UV curing systems is expected to reduce the power consumption and CO2 emissions of offset printing.

We also offer environmentally friendly materials such as "Limestone," "Biomass Adhesive," and "Recycled PET." If you are interested in eco-friendly materials, please check the following materials.

Kojima Label Printing|Environmentally Friendly Materials

Print Products Suitable and Unsuitable for Offset Printing

Offset printing is suitable for print products that require consistent quality in large quantities, have large paper sizes, or where color reproduction is critical.

Typical print products suitable for offset printing include:

【Print Products Suitable for Offset Printing】

- Books

- Magazines

- Catalogs

- Posters

- Flyers

- Packaging

- Stickers and Labels

On the other hand, the main types of print products that are not suitable for offset printing have the following characteristics:

【Print Products Unsuitable for Offset Printing】

- Include variable elements (possible with separate processes)

- Small paper sizes

- Small print runs

For print products with unsuitable elements, it is recommended to consider other printing methods or consult with the printing company.

We offer label production using this method. To see examples of our work, click below.

【Offset Printing Work Examples】

2 Points to Note When Ordering Offset Printing

Finally, here are some points to note when ordering offset printing.

【Offset Printing Work Examples】

- Is the quality of the manuscript optimal?

- Have you checked for typographical errors, fonts, and text?

Knowing these points can help reduce the risk of failure.

Point 1: Is the Quality of the Manuscript Optimal?

When ordering offset printing, request a design created in CMYK color mode. CMYK color mode uses four colors: C (cyan), M (magenta), Y (yellow), and K (black).

If you request a design created in RGB color mode* used for TV and computer displays, the colors may change when converted to CMYK. *RGB color mode creates colors by mixing the three primary colors of light: Red, Green, and Blue.

To create a design in CMYK color mode, it is important to set the CMYK mode when creating with software like Illustrator or Photoshop. However, if there are minor issues with the submitted data, we offer support, so feel free to consult with us.

For more information on creating print data in CMYK, please read the article below.

How and Why to Create Print Data in CMYK. Differences with RGB Explained

Point 2: Have You Checked for Typographical Errors, Fonts, and Text?

When ordering offset printing, it is essential to check for typographical errors, and also to confirm the fonts and text. Particularly important is the confirmation of whether the fonts and text have been outlined. Outlining refers to the process of converting text and shape information.

If not outlined, the fonts may be replaced, leading to text garbling. When submitting data, it is important to also send the finished image data in PDF format and confirm with the printing company that there are no discrepancies in the data.

For more details on submitting data, please read the following article.

Kojima Label Printing|Data Submission Guide

Offset Printing is Recommended for Large Quantity Printing and Beautiful Finishes

This method uses "plates" and allows for large quantity production with high color accuracy and quality finishes. It can flexibly accommodate large paper sizes, making it suitable for posters, oversized flyers, and various sizes of printed materials.

It is ideal for products that require consistent quality in large quantities, large paper sizes, or where color reproduction is critical. However, it is not suitable for variable runs or small quantities.

If you are considering producing high-quality materials that leverage these characteristics, please feel free to contact us below. Our experienced professionals will provide tailored solutions to meet your needs.

Start Your Project Now!

Contact Us or Get a Quote!