Embossed Labels Explained | Elevate Your Impressions!

Products with embossed labels on their packaging convey the manufacturer's commitment. Running your fingers over the surface reveals a design with raised and recessed areas. This time, we will explain embossing, a process that adds value to your design with just a little extra effort.

Please feel free to contact us.

What is an Embossed Label?

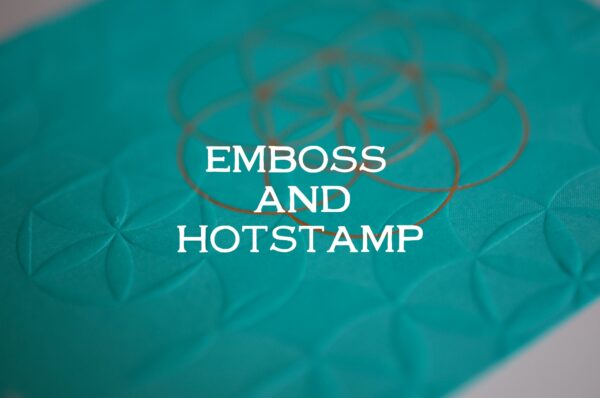

Embossed labels are made by applying pressure to paper material with a special plate, creating a raised and recessed effect. These labels are typically used to highlight elements like brand logos or product names on packaging. Although subtle, they exude a sense of luxury and are therefore used in various applications. The image below shows an embossed label with a recessed background and raised text on silver foil paper. As shown, embossing can be freely designed to create raised and recessed patterns.

The embossed texture makes the design stand out even without printing.

Processing Method

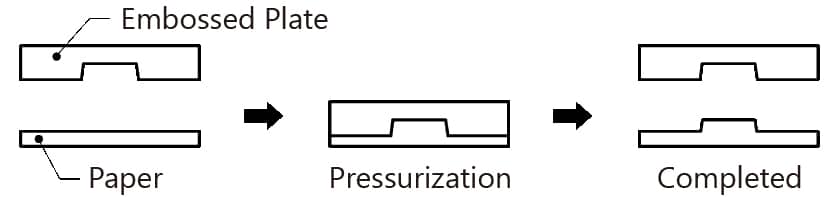

Label material pressed by a machine is forced into the grooves of the embossing plate. When the plate is removed, the grooves leave an impression on the label, creating the embossed effect.

Suitable Materials for Embossing

Paper Material → Suitable

Film Material → Not Suitable

Unlike printing, embossing designs raised and recessed patterns directly onto the material. Paper material is suitable for embossing because it deforms under pressure and retains its new shape. In contrast, film material is difficult to deform and tends to return to its original shape, making it unsuitable for embossing. Although film material can be slightly embossed, it lacks the sharp edges of embossed paper.

Here are some materials suitable for embossing:

・High-quality paper (various types)

・Art paper

・Mirror-coated (gloss) paper

・Gold foil paper (gloss and matte)

・Silver foil paper (gloss and matte)

・Washi (Japanese paper)

・Embossed tack paper

If you want to create a deep emboss, consider using laminated paper (two layers of material) to make the embossing stand out more.

Design Suitability

Embossing reproduces designs through raised and recessed patterns, making it unsuitable for intricate illustrations. Fine designs may not stand out because the paper cannot fit into the plate's grooves. Fonts with fine lines, like Mincho, and detailed patterns are unsuitable for embossing. To ensure the design's suitability, consult with the label printing company or conduct a proof test (available for around 6,000 to 10,000 yen).

Summary of Embossed Labels

- Embossing creates raised and recessed patterns by applying pressure to the material.

- Film materials are not suitable for embossing as the edges are not well-defined under pressure; paper materials are ideal.

- Intricate designs are not suitable for embossing.

- If possible, confirm the design with a proof test before mass production.

- Designs with 1-2 colors are economical and recommended.

Embossed Stickers | Product Page

Design the surface texture.

We have created free samples of embossed stickers. Feel free to contact us.

Start Your Project Now!

Contact Us or Get a Quote!